Brunton Shaw UK, a key manufacturing unit of the Usha Martin Group, is proud to announce the successful production and in-house proof load testing of its latest OceanFibre heavy lift sling. Engineered at our state-of-the-art facility in the United Kingdom, this sling exemplifies our unwavering commitment to quality, safety, and high-performance lifting solutions.

Designed for the most demanding heavy-lift operations, the OceanFibre sling was rigorously tested on our 2,000-ton capacity test bed, reaffirming its reliability and structural integrity. The product highlights reflect the exceptional craftsmanship and precision engineering that define our manufacturing excellence:

Each OceanFibre sling is meticulously designed, manufactured, and tested to meet the highest global standards. With no room for compromise in critical heavy-lift applications, our team ensures absolute accuracy at every stage of production.

OceanFibre. Engineered for precision. Certified for performance.

Brunton Shaw UK remains committed to advancing lifting technology and delivering safe, dependable solutions to customers worldwide.

We are proud to announce that our manufacturing unit at Ranchi has been awarded the Bronze Medal by EcoVadis, a leading global provider of business sustainability ratings. This recognition marks a significant milestone in our Environmental, Social, and Governance (ESG) journey.

This reflects our ongoing commitment to sustainable business practices across key areas, including environmental stewardship, labour and human rights, ethics and sustainable procurement.

This achievement is a testament to the collective effort, dedication, and valuable contributions of our entire Usha Martin team. We extend our sincere gratitude to every employee whose commitment made this possible.

The newly constructed Pedestrian Cable-Stayed Bridge at Pune Metro, connecting Chhatrapati Sambhaji Udyan Metro Station to Shaniwar Peth, stands as a symbol of innovative and modern engineering.

Usha Martin is honoured to have contributed to this landmark infrastructure project by supplying our high-quality HDPE coated LRPC (Low Relaxation Pre-Stressing Concrete) strands. These specialized strands ensure the necessary strength and structural stability required to withstand dynamic loads, supporting the movement of over 2 lakh daily metro commuters.

Shaped like a 'veena', an Indian musical instrument, this iconic structure is Pune city’s longest flyover and the first cable-stayed pedestrian bridge across the Mutha River. We are proud to be associated with such significant milestones and remain committed to powering critical infrastructure projects globally.

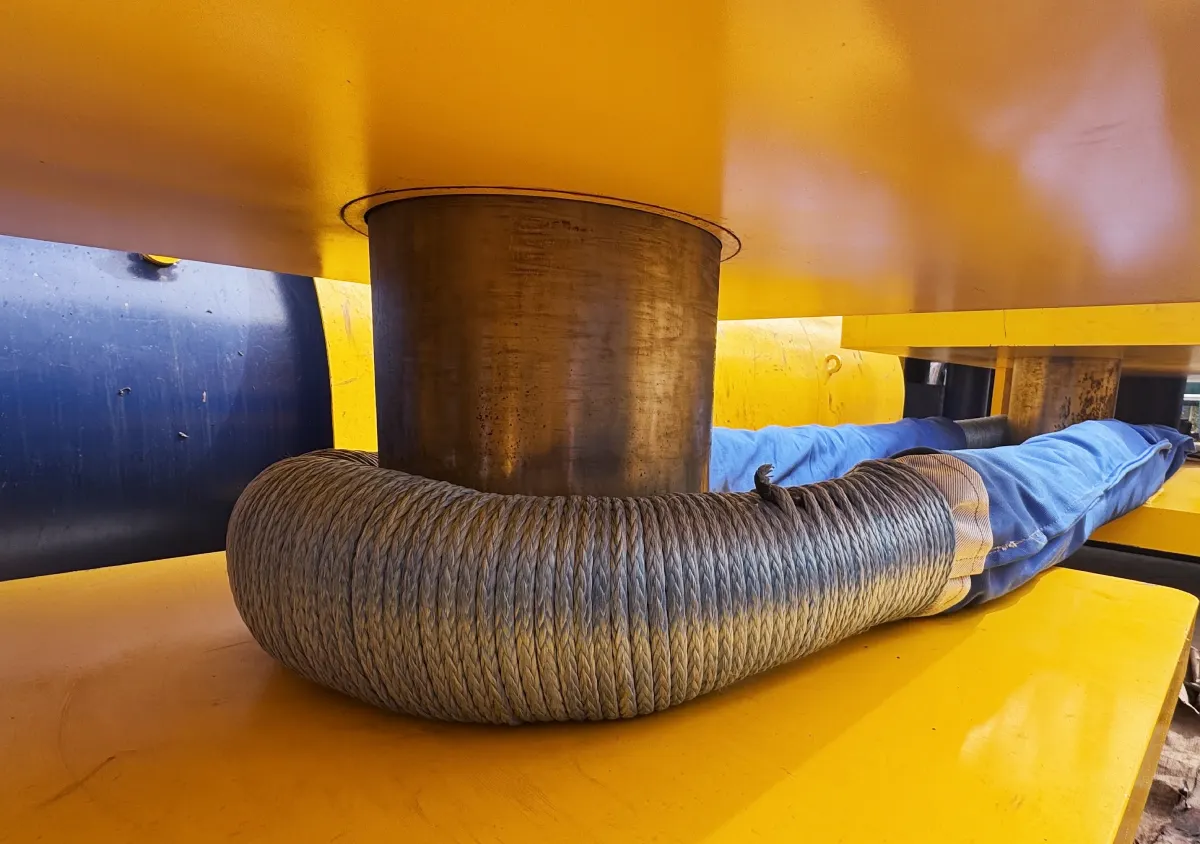

Witness the journey of our record manufacturing of high-performance, large diameter crane ropes, each weighing 160 tonnes, produced at our state-of-the-art Ranchi facility. Engineered with the unique core lubrication retention system, these wire ropes deliver superior durability and reliability while operating under challenging environments.

Specially designed to power one of the world’s largest high-capacity floating cranes, these ropes enhance productivity while ensuring the highest standards of safety and quality.

This milestone stands as a true testament to our engineering expertise, advanced manufacturing capabilities, and commitment to delivering world-class ropes for the most demanding applications.

At Usha Martin, we continue to set new benchmarks with our future-ready wire rope solutions.

We are excited to share our contribution to a landmark infrastructure project in Bihar. The newly constructed cable-suspension bridge over the Punpun River in Patna district, has been built by Apicon Real Infra Pvt Limited and installed with Usha Martin’s specially designed 72 mm diameter Locked Coil Wire Ropes, engineered for superior strength, stability, and safety.

Inaugurated by Hon’ble Chief Minister of Bihar, Shri Nitish Kumar, the bridge stands as a testament to engineering excellence and sustainable development. Located near the Punpun Pinddaan site, it will greatly enhance accessibility for pilgrims while enriching the cultural heritage of the region.

At Usha Martin, we are proud to support transformative projects that build resilient infrastructure and strengthen communities. We remain committed to delivering trusted engineering solutions that drive the nation’s progress.

_banner_20250730112720.webp)

Usha Martin Limited is proud to announce its participation as a signatory to the United Nations Global Compact (UNGC), the world’s largest corporate sustainability initiative. With many participants across the globe, the UNGC represents the largest corporate sustainability initiative in the world.

The UNGC calls on companies to align their strategies and operations with universal principles on human rights, labour, environment, and anti-corruption, while taking concrete actions to support broader societal goals. By joining this initiative, Usha Martin reinforces its commitment to aligning business operations with the Ten Principles of the UNGC across these four critical areas.

This achievement highlights Usha Martin's dedication to responsible business practices, ethical governance, and building a sustainable and inclusive future. The company looks forward to actively contributing to the UNGC's global mission through its initiatives and actions, while supporting the advancement of the Sustainable Development Goals (SDGs).

We’re proud to share that the newly inaugurated Ambargodlu–Kalasavalli Bridge in Sagar (Shivamogga), Karnataka - India’s second-longest cable-stayed bridge over the Sharavathi backwaters—features our advanced engineering solutions.

The bridge is installed with 96 cables made from Usha Martin’s HDPE polymer-coated bonded LRPC strands, anchored on four pylons. These high-performance strands are specially designed to offer superior corrosion resistance and structural stability, ensuring durability under dynamic load conditions.

Inaugurated by Union Minister Shri Nitin Gadkari, this infrastructure marvel, approved by MoRTH as the country’s eighth extra-dosed cable-stayed cum balanced cantilever bridge, marks a significant milestone in regional connectivity and development.

At Usha Martin, we take immense pride in supporting the development of the nation’s infrastructure.

Usha Martin Limited is proud to support the Agra Metro Railway project by manufacturing and supplying 2,500 tons of high-quality Low Relaxation Prestressed Concrete (LRPC) strands, along with complete prestressing solutions for a 7.5 km elevated corridor, constructed by Larsen & Toubro Ltd.

Our state-of-the-art products are designed to withstand dynamic loads and ensure structural stability, contributing to the development of modern and sustainable infrastructure.

This project enhances urban mobility in Agra, providing efficient transportation for residents and visitors.

At Usha Martin Limited, we are committed to delivering advanced engineering solutions that drive India’s progress.

Usha Martin takes immense pride in contributing to the successful installation of the iconic Chenab Bridge in Kashmir, the world’s highest railway arch bridge, inaugurated on 7th June 2025 by Hon’ble Prime Minister Shri Narendra Modi.

Our in-house designed and manufactured locked coil wire ropes were installed on the cable cranes, playing a key role in lifting and placing nearly every segment of this monumental structure. From the project’s inception, our team worked closely with project authorities, consultants, and contractors to ensure precision engineering and flawless execution at every stage.

Even post-completion, the authorities have chosen to retain Usha Martin’s wire ropes on the cable crane as a proactive measure for future maintenance and safety, a testament to their reliability and performance.

This landmark achievement is not just a milestone but a moment of national pride as we continue to support India’s growing infrastructure with cutting-edge engineering solutions.

Usha Siam Steel Industries Public Co. Ltd., our manufacturing unit in Thailand, has expanded its specialized fine cord production line with cutting-edge technology. The new facility reinforces the Group’s commitment to innovation and global supply chain excellence.

The upgraded production line incorporates advanced wire drawing, stranding, and closing machines, optimizing efficiency while reducing manual dependency. This strategic enhancement enables Usha Siam to deliver a new range of products and cater to evolving industry demands worldwide.

Key Offerings from the Expanded Facility Include:

Usha Siam leverages a robust international distribution network, ensuring seamless access to global markets. This expansion marks another step forward in the Group’s mission to drive innovation and deliver superior solutions across industries.

Oceanfibre HMPE Round Slings are setting new benchmarks in offshore lifting solutions. Designed to excel in the harshest environments, these high-performance slings are the preferred choice for critical subsea and topside operations, delivering unmatched strength, durability, and reliability.

We recently supplied customized Oceanfibre HMPE Round Slings to an esteemed client, featuring:

Equipped with ROV grab handles for seamless subsea handling. 100% designed, manufactured, and proof-loaded in-house

Engineered with cutting-edge High Modulus Polyethylene (HMPE), Oceanfibre Round Slings offers superior resistance to abrasion, chemicals, and UV exposure, making them ideal for demanding offshore applications.

Usha Martin introduces GALSTAR™ wires, an innovative solution designed to provide superior protection against corrosion, outperforming traditional zinc coatings. These wires provide unparalleled corrosion resistance, maintaining structural integrity even after significant deformation or heat exposure. The advanced zinc-aluminium alloy combines zinc’s sacrificial protection with aluminium’s passivation properties, eliminating the need for costly, complex, and environmentally harmful post-coating processes.

Setting a new benchmark in quality, GALSTAR™ wires excel in both low and high carbon products, making them the ideal choice for critical applications such as:

Engineered with a zinc-aluminium alloy coating, GALSTAR™ meets stringent national and international standards, ensuring unmatched durability, reliability, and performance.

With GALSTAR™, Usha Martin continues to lead the industry in delivering cutting-edge wire solutions for the most demanding applications.

Usha Martin Limited is proud to announce that it has been accredited with the Authorized Economic Operator (AEO) T-2 Certification by the International Directorate of Customs (DIC), New Delhi. This significant recognition, granted under the World Customs Organization (WCO) SAFE Framework of Standards, marks a major milestone in the company’s journey toward operational excellence and enhanced global trade facilitation.

The AEO T-2 certification reflects Usha Martin’s steadfast commitment to ensuring the highest standards of compliance, security, and efficiency in its international supply chain operations. As part of the Government of India’s initiative to streamline trade under the WTO Trade Facilitation Agreement, this certification underscores our alignment with global best practices.

Key Benefits of AEO T-2 Certification:

This recognition is not just a certification—it is a testament to our collective efforts in driving innovation, fostering regulatory compliance, and strengthening partnerships across the global logistics ecosystem.

We are honoured to receive the AEO T-2 Certification and sincerely thank the Customs Authorities and the International Directorate of Customs for this recognition. This achievement further motivates us to continue delivering value through secure and efficient trade practices worldwide.

Usha Martin is honoured to be part of the newly inaugurated Pamban Bridge in Tamil Nadu, unveiled by our Honourable Prime Minister, Narendra Modi, on April 6, 2025. This engineering marvel, India’s first vertical lift railway sea bridge, sets a new benchmark for sea connectivity and infrastructure innovation, and we are immensely proud to have contributed to such a groundbreaking project.

The Pamban Bridge, which connects Rameswaram Island to the mainland, is not just a testament to India’s growing engineering capabilities but also a symbol of innovation and resilience. This iconic structure is operated with high-tech, precisely engineered structural wire ropes from Usha Martin. With a diameter of 46 mm, these wire ropes have been specifically designed to withstand the region’s challenging environmental conditions.

From the very inception of this project, Usha Martin’s team worked hand-in-hand with the project implementer and design consultant to ensure the bridge met the highest standards of engineering excellence through our cutting-edge wire rope solutions.

We are privileged to have contributed to this remarkable project, which stands as a testament to our nation’s progress and vision.

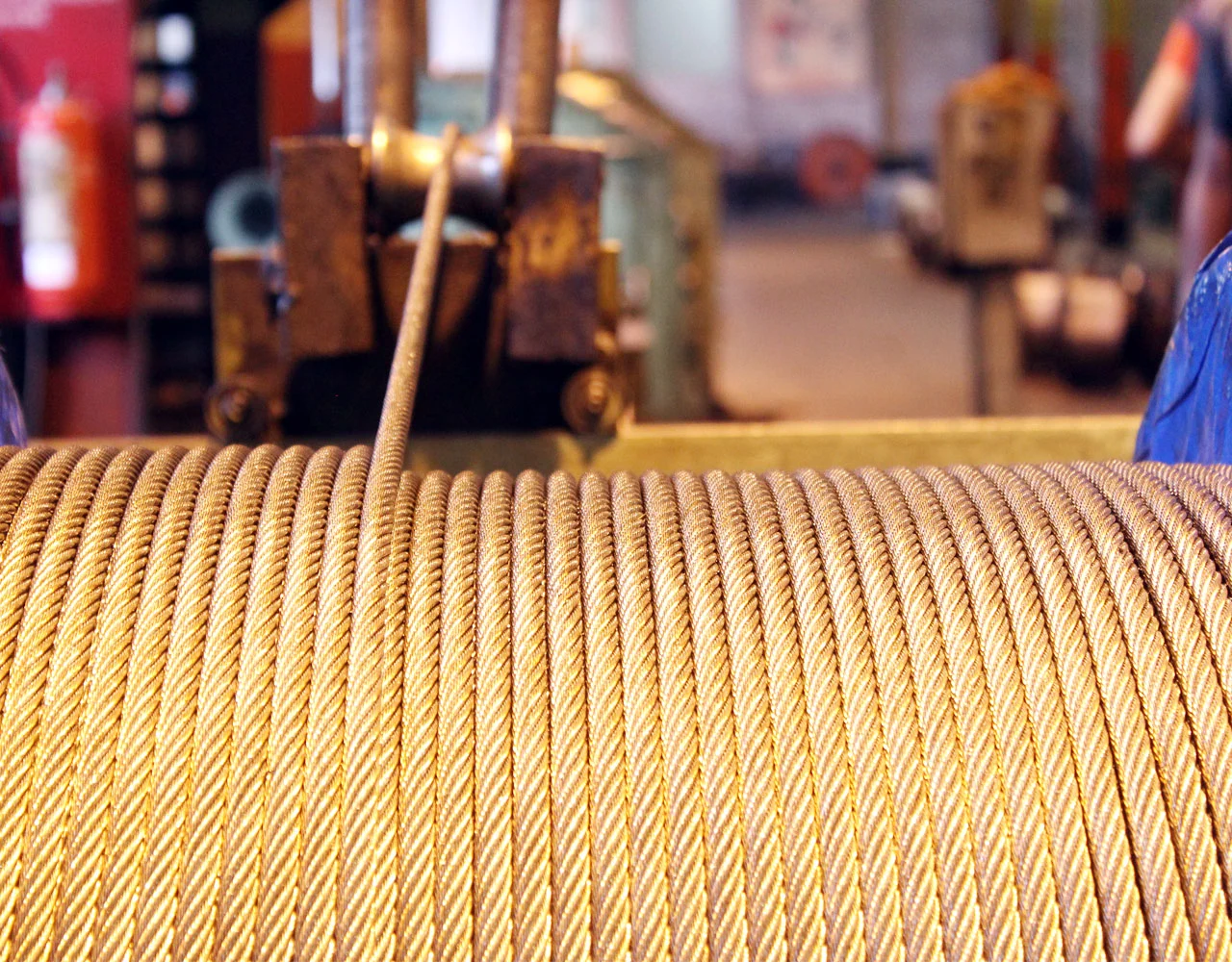

Our international operations, De Ruiter Staalkabel and Brunton Shaw UK were granted a special project by one of its esteemed customers; Huisman Equipment.

Huisman has been a long-standing and loyal client to De Ruiter Staalkabel and the Usha Martin Group.

As a specialist in the field of high-tech wire ropes and related installation and service activities, we were awarded supply of a complete dress of wire ropes to be installed in one of Huisman’s industry-leading 2600T leg encircling crane. This crane is currently successfully operating on board of #Cadeler’s WIND MAKER, one of its state-of-the-art, jack-up wind turbine installation vessels.

Our assignment included design, production, quality control, 3rd party certification and delivery of all high-tech OCEANMAX wire ropes into China.

For this high-profile project, the overall supply entailed 2 x 2350 meter, 72mm, OCEANMAX8 main hoist wire ropes, 1 x 4300 meter, 72mm, OCEANMAX8 boom hoist wire rope and a 1165 meter, 72mm, OCEANMAX35 auxiliary hoist wire rope.

For this job, the engineers of De Ruiter Staalkabel involved its respective counterparts within the Usha Martin Group. Our Global Development Centre (GDC) in Italy ensured for a safe and high-performance design & engineering. Consequently, the wire rope was produced according to the highest standards by Brunton Shaw UK, our high-tech wire rope division within the Usha Martin Group. Both companies are well-experienced towards the Offshore Wind & Energy markets and all cooperated seamlessly to provide timely delivery of the OCEANMAX wire ropes in question.

We specifically wish to thank Huisman Equipment for its confidence and trust. The continuous support and cooperation of its Engineering Team proved to be a very successful combination towards the successful completion of this project.

For more information on our world-wide capabilities please contact us at sales@drstk.nl or visit our web site at www.deruiterstaalkabel.nl.

Wire ropes are indispensable components of elevator systems, supporting their safe and reliable operation while ensuring the comfort and safety of passengers during vertical transportation. The reliability and durability of wire ropes are essential for ensuring the safety of elevator passengers. Elevator ropes contribute to the smooth and efficient operation of elevators by providing consistent traction and minimizing friction as they glide along the sheaves or pulleys. This smooth operation enhances the overall ride quality and passenger experience.

In recent times, governmental actions such as the UP Lift Bill aim to enhance elevator safety regulations, mandating registration, emergency drills, and stringent oversight. These measures seek to mitigate risks and ensure the well-being of elevator users. Keeping abreast of safety protocols, conducting routine maintenance checks, and prioritizing upgrades are integral steps toward safeguarding elevator users.

Usha Martin emerges as a beacon of reliability and safety in the elevator industry. With a commitment to superior quality, Usha Martin offers high-quality, pre-stretched, low-elongation wire ropes to ensure optimum service life and the highest safety standards for elevators. Engineered to withstand the rigors of elevator operation, these ropes offer peace of mind and safety assurance.

Usha Martin offers a comprehensive range of ropes, from hoist ropes to compensating ropes to governor ropes, catering to diverse elevator requirements. This ensures smooth and secure vertical transportation. Accredited with ISO certifications and trusted by the leading elevator OEMs, Usha Martin sets the benchmark for excellence in elevator wire ropes. Elevator hoisting ropes are designed with close dimensional tolerances to facilitate jerk-free movement.

High-Quality Wire Ropes: Our products are manufactured using advanced state-of-the-art technology and undergo strict quality control measures to meet stringent industry standards and specifications, ensuring reliability, strength, and durability for superior performance.

Testing and Quality Assurance: The hoisting ropes are closely monitored to ensure desired tolerances are met, and the diameter is consistent to ensure correct contact between the rope and groove. Additionally, routine and regular testing for fatigue endurance, elongation characteristics, and diameter stability are carried out in a dedicated fatigue test facility to deliver consistent rope performance.

Customized Solutions: Usha Martin works closely with elevator OEMs to develop customized wire rope solutions tailored to the specific requirements of different elevator systems. By understanding the unique needs of elevator installations, Usha Martin can provide ropes optimized for performance and safety.

Compliance with Standards: Usha Martin ensures that its wire ropes comply with relevant safety standards and regulations governing elevator components. This commitment to regulatory compliance ensures that the wire ropes meet strict safety criteria and contribute to the overall safety of elevator systems.

Technical Support and Training: We provide technical support and training to elevator manufacturers, installers, and maintenance personnel to ensure proper handling, installation, and maintenance of wire ropes. By imparting knowledge and best practices, Usha Martin helps maximize the safety and reliability of elevator systems.

Continuous Improvement: We are committed to continuous improvement and innovation in wire rope technology. By investing in research and development, Usha Martin strives to enhance the safety, performance, and longevity of its wire ropes, thereby contributing to the overall safety of elevators.

Usha Martin is an approved supplier to many international elevator manufacturers. Our capacity to cater to the leading elevator OEMs with all types of high-performance elevator ropes and value-added services has positioned Usha Martin as one of the most preferred wire rope brands in the world today.

Let's elevate safety standards, one high-quality wire rope at a time, with Usha Martin.

The 12th Lifting and Rigging Seminar took place in Amsterdam, which was organised by the International Marine Contractors Association (IMCA). It brought together many industry professionals from Europe, South Africa, and North and South America. The international conference focused on the technical and operational challenges posed by increasingly heavier lifts in the offshore wind sector. Allen Leatt, IMCA’s Chief Executive Officer inaugurated the 12th Lifting and Rigging Seminar and said that the focus for this year’s seminar is on lifting technology in the offshore wind sector.

Laura Lombardi, Managing Director, Usha Martin Italia and Chairperson of IMCA’s Lifting & Rigging Management Committee (LRMC) shares her thoughts on the recent Lifting & Rigging Seminar, held in Amsterdam.

Laura Lombardi is the Managing Director of Usha Martin Italia, which is the technical and R&D center of Usha Martin Group, a global manufacturer of high-performance wire ropes. Laura has a Bachelor’s degree in Mechanical Engineering and has been involved with IMCA since 2010. She became the vice chairperson of LRMC in 2016 and chairperson in February 2021.

The Lifting & Rigging Seminar is put together by a workgroup, comprising people involved in the LRMC’s work. Hence, they are all IMCA members with vast experience and in-depth knowledge of offshore lifting activities within our industry. The LRMC generates these events as forums for discussion between members and non-members alike with a focus on critical technical and operational topics. Bringing together a mixture of presentations and workshops allows attendees to focus on specific topics during the day, identifying the actual state of the industry and its future requirements and encouraging contractors, suppliers, and representatives from regulatory bodies to share their experiences and needs.

In this conference, Laura stepped at the last minute to Chair the seminar on the day as unfortunately David Cannell from TechnipFMC, who has traditionally fronted this event, was unable to attend. Our thanks go to David for his great contribution to getting in touch with the speakers and developing the event and we look forward to his return at the next seminar.

The theme focused on the technical side of offshore lifting and the challenges created in the renewable energy market, which is stretching the vessels and equipment capabilities, with components that are continuously getting bigger and more complex. We had a great speaker lineup with contributions from all areas of the industry, and I would like to thank each of them for their time and efforts in being part of this event and sincerely thank all attendees for their interaction.

We also had a dedicated open panel with the suppliers, in which questions and answers were shared and good discussions were initiated.

Laura said: this seminar was part of a series of events that commenced in 2012 and focused on high-value offshore wire ropes. The seminars have proven to be a great platform for the subsea contractors to discuss their issues and concerns with various equipment suppliers to come up with effective solutions for the future. Over the years, we had great discussions and have seen significant changes in the approach taken to the care and maintenance of high-value steel wire ropes within the industry. In 2018, we took the decision to return to offshore cranes. The workshops during the 2018 seminar were used to identify the industry needs and crucial topics related to offshore cranes. From this, we identified the training needs of personnel, offshore lift planning, digitalisation of offshore cranes, and general crane technology requirements. In 2019, we covered training & personnel competencies. In 2020, we were hit by COVID. However, IMCA still ran a webinar that covered Crane Systems and Offshore Lifting.

A review of some of IMCA’s key lifting documents was presented in this recent seminar, which included guidance on the selection of wire ropes, storage, transport, maintenance, discard criteria, and factors causing wire rope deterioration. This document also included the use of non-destructive examination (NDE) by means of MRT for wire ropes, to assist with inspection and integrity management.

Laura reminded everyone that the next IMCA Lifting and Rigging Seminar would take place on 26th October 2023 in Amsterdam and hoped to see everyone again.

You can register yourself and sponsorship opportunities are available. Detailed information can be viewed on IMCA Lifting & Rigging Seminar 2023 – IMCA (imca-int.com).

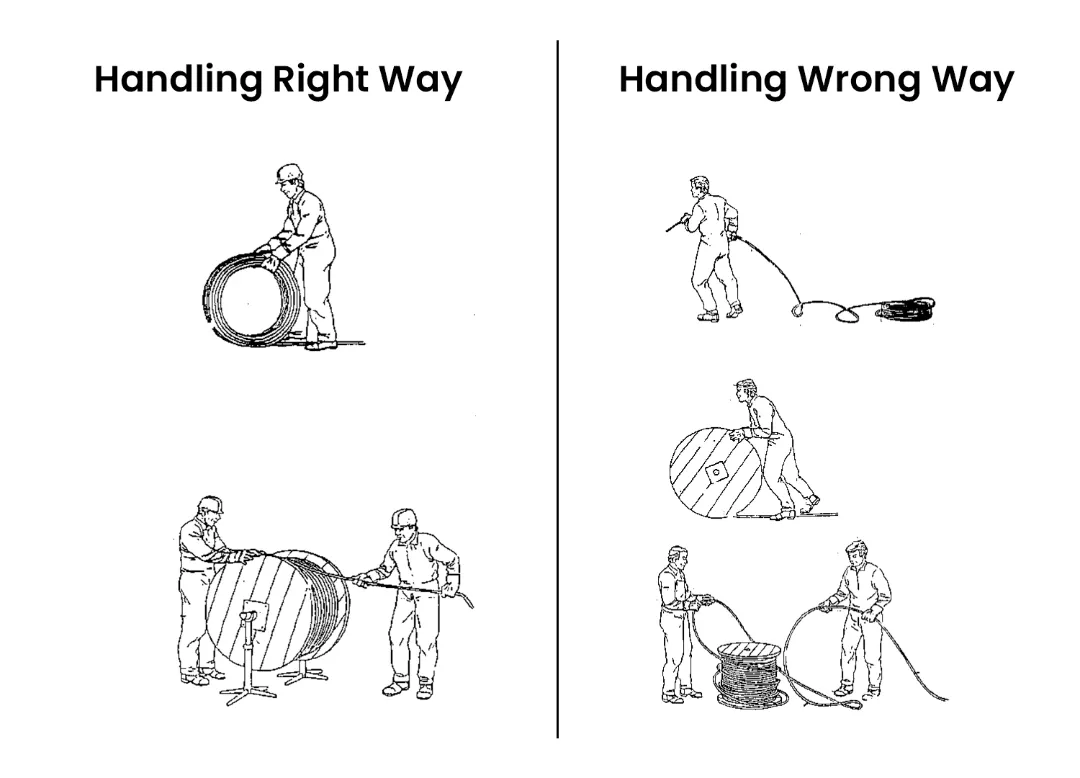

Usha Martin’s specially designed high-performance wire ropes are one of the most crucial components in heavy-duty cranes, without which the cranes can’t function at all. Our wire rope ensures a longer operational life and minimises downtime costs. Proper storage, installation, maintenance, lubrication, and discard of wire rope needs to be carried out as per international standard ISO 4309 to extract the maximum life from our products.

Proper Storage of wire ropes

Storage

Wire rope lubrication

A wire rope is a piece of machinery with many moving parts (wires-strands) and as such it is subjected to internal and external friction causing wear and corrosion.

Suitable lubricants are applied during the manufacturing of the core, the strands, and finally the finished ropes. The service lubricant should be compatible with the original lubricant used by the wire rope company.

A good lubricant must have the following properties:

Rope lubrication during manufacturing:

Basic discard criteria of wire ropes

Broken wires

Increase in rope diameter: This characteristic is often related to a change in the condition of the core, such as a fibre core swelling up due to the absorption of moisture or the accumulation of corrosion debris within the rope.

If the rope diameter increases by 5 % or more in a rope with a steel core or 10 % or more in a rope with fibre core during service, the reason for this shall be investigated and consideration is given to discarding the rope.

Decrease in rope diameter: A decrease in rope diameter can result from a number of factors, one of which is external wear. Usually results from contact with sheaves or drums or from the pressure of rope on the rope, as would be expected at the cross-over zones as the rope traverses the drum. More pronounced amounts of wear are usually found in those sections of rope which are in contact with the grooves of sheaves and drums when the load is being accelerated or decelerated. A lack of lubrication and the presence of abrasive dust can also affect the rate of wear. In addition to the obvious visible mode of deterioration described above, the rope can also decrease as a result of one or a number of internal mechanisms, such as:

Conclusion: We at Usha Martin are committed to working together with our customers to extract the optimum life cycle from our wire ropes. Therefore, proper storage, handling & installation of wire rope is crucial. Thus, being one of the leading wire rope manufacturers, we follow international standards as per ISO 4309 in helping our end-users to achieve maximum performance from our products.

The wire ropes manufactured by Usha Martin are today catering to some of the most critical applications for almost all industrial sectors. Our wire ropes undergo stringent quality testing measures to ensure utmost safety with the highest quality standards that help to deliver high-performance ropes for different applications. With six decades of experience, we engineer in offering a wide range of products that suits all types of critical environment.

Special operations like compaction, plastication, and pre-stretching are induced to enhance product properties and performance. Usha Martin is probably the only company in the world that can provide a one-stop solution/ system guarantee of entire pre-stressing activities, having supply capability of all the required components backed up by a specialized service team and equipment.

In this blog, let us discuss the application of wire ropes used in Ports and Mines.

As transportation of goods by sea is more economical than either air or land, hence worldwide logistics through ships play a major role in the smooth functioning of business by carrying a huge volume of goods and materials from one country to another. Here ports play a major role, where goods are unloaded in the form of containerized loads or bulk material from the ships.

Unloading the goods from vessels within a limited timeframe is one of the biggest challenges faced by port terminals. Very high-capacity cranes are deployed in both container terminals and bulk material handling terminals to carry out these enormous tasks, which operate at a level of 50-60 meters above the ground. Here, the quality and life cycle of the wire ropes installed on heavy-duty cranes are crucial as they affect the downtime cost.

Usha Martin’s specially designed high-quality wire ropes are one of the most crucial components used in these heavy-duty cranes, without which the cranes can’t function at all.

A few key factors for preferring the Usha Martin brand are:

Over the years, we have developed a wide range of high-performance wire ropes, including plastic-impregnated compacted ropes with special properties that have delivered excellent results for our customers and helped to enhance operational efficiency in ports. To learn more about our crane ropes, visit https://ushamartin.com/products/crane-rope

Wire ropes are extensively used in mining applications, both in underground and surface mining. After excavation, wire ropes play a significant role in lifting and moving the ores, ensuring maximum safety of workers and equipment both in opencast and underground mines. Usha Martin spearheads the safety “movement” in mines by providing wire ropes with higher resistance to fatigue, wear & abrasion, ensuring longer operational life with minimum downtime cost.

Usha Martin has developed plasticated-valley-filled ropes, which are used extensively in very high-capacity shovels and draglines in opencast mines. Specially designed locked coil winding ropes are deployed for the safest movement of man & material in underground mines.

When it comes to critical operations in mining, global mining companies rely on us. Our wire ropes find applications in the following mining equipment:

To know more about our products used in mines, visit: https://ushamartin.com/products/mining-rope

Conclusion

Usha Martin is one of the largest manufacturers of wire ropes in the world, supported by six global manufacturing units and service centers spread across the world. Our Global R&D center, located in Italy, has been at the forefront of finding innovative solutions for industry-wise technical needs, with a special focus on designing high-quality wire ropes for the critical and sophisticated application that meets your requirement under extremely adverse conditions. Over the years, we have built a robust network globally to offer our customers a comprehensive range of international quality products ensuring smooth delivery and uninterrupted service.

Usha Martin has always been one of those organizations that have contributed to the nation's development over the last six decades. This has helped to build the nation's infrastructure with our value-added products and solutions. The company offers high-performance wire ropes, PE-coated bonded/ un-bonded LRPC strands, and prestressing solutions, backed up by the expert installation team for pre-tensioning and post-tensioning jobs for infrastructural projects. Usha Martin is the only company in India and probably in the world to provide one-stop prestressing solutions. We are proud to be associated with the infrastructural growth of the nation, especially in transportation, be it elevated expressways, cable-stayed bridges, metro projects, nuclear reactors, urban development, and so on.

So, let's take a look at some of the key installations from Usha Martin.

Within 60 years of experience in the industry, we have been involved in many substantial projects:

Usha Martin is proud to be a part of this iconic installation. The world's highest railway arch bridge over the River Chenab in Kashmir. Usha Martin designed and manufactured the locked coil wire ropes installed on the 'cable cranes', which have been used to move almost all the segments of the bridge during its construction. The company has supplied the wire ropes for the cranes used in this project.

The Durgam Cheruvu cable-stayed bridge is an extradosed bridge in Hyderabad, India. Usha Martin executed the complete internal prestressing contract for the concrete deck with the supply of LRPC strands. This is the longest bridge in Hyderabad, with a total length of 233 meters.

Kailash gate bridge, also known as Janki Setu bridge, located at Rishikesh in Uttarakhand, is the first three-lane bridge in the state of Uttarakhand in India. Usha Martin has been an integral part of this project. The semi-vehicular cable suspension bridge has been installed with spiral strand ropes, which were manufactured and supplied by Usha Martin. The bridge has a total length of 346 meters, with a span of 274 meters.

Dobra Chanthi Bridge is India's longest motorable cable suspension bridge with a 440-meter span, built on Tehri Dam in Uttarakhand. The bridge was installed with 66 mm diameter high-quality locked coil bridge ropes designed and manufactured by Usha Martin. The suspension bridge adds enormous value to the society of the Tehri district.

Polymer-coated wax-filled LRPC strands manufactured by Usha Martin have been installed as stay cables components in the Rail-Over-Bridge (ROB) at Burdwan station in West Bengal. Usha Martin supplied the specially designed cables for this project under the 'Make-in-India' policy.

Auli Ropeway is one of the longest ropeways in India, which connects Joshimath with Auli in Uttarakhand. With a height of 3016 meters above sea level, the bi-cable ropeway is installed with high-quality haulage ropes manufactured and supplied by Usha Martin. Our haulage ropes have been hassle-free and maintenance-free for nearly a decade since they were installed. Auli Ropeway is the major attraction in Auli, which covers a distance of 4.15 km, offering visitors a magnificent view of the Himalayan mountains.

Naini Bridge, also known as New Yamuna Bridge, is a Cable-Stayed Bridge at Prayagraj (Allahabad) in the state of Uttar Pradesh in India. The four-lane cable-stayed bridge is installed with specially designed locked coil steel wire ropes manufactured and supplied by Usha Martin. The total length of the bridge is 1510 meters, with a span of 260 meters. This landmark installation, suspended with high-quality wire ropes of Usha Martin, ensures the utmost safety for millions of lives moving over it.

The aforementioned works of Usha Martin in India are some of the notable contributions of the company. Besides making an active contribution to building India, the company is also continuously strengthening its overseas operations to maintain its leadership position in the global market.

Usha Martin's Global Design Centre, located in Italy, is actively engaged in designing high-performance wire ropes to develop products that are the best in class. The manufacturing facilities are located in India, the UK, Thailand, and UAE. Our distribution, sales, and service centers are spread across the world at strategic locations to provide uninterrupted and customized services to our clients.

Usha Martin has emerged as one of the leading wire rope manufacturers and suppliers, helping the nation to build the infrastructure required to strengthen the foundation for tomorrow.

To learn more about our products and solutions reach us at contact@ushamartin.co.in

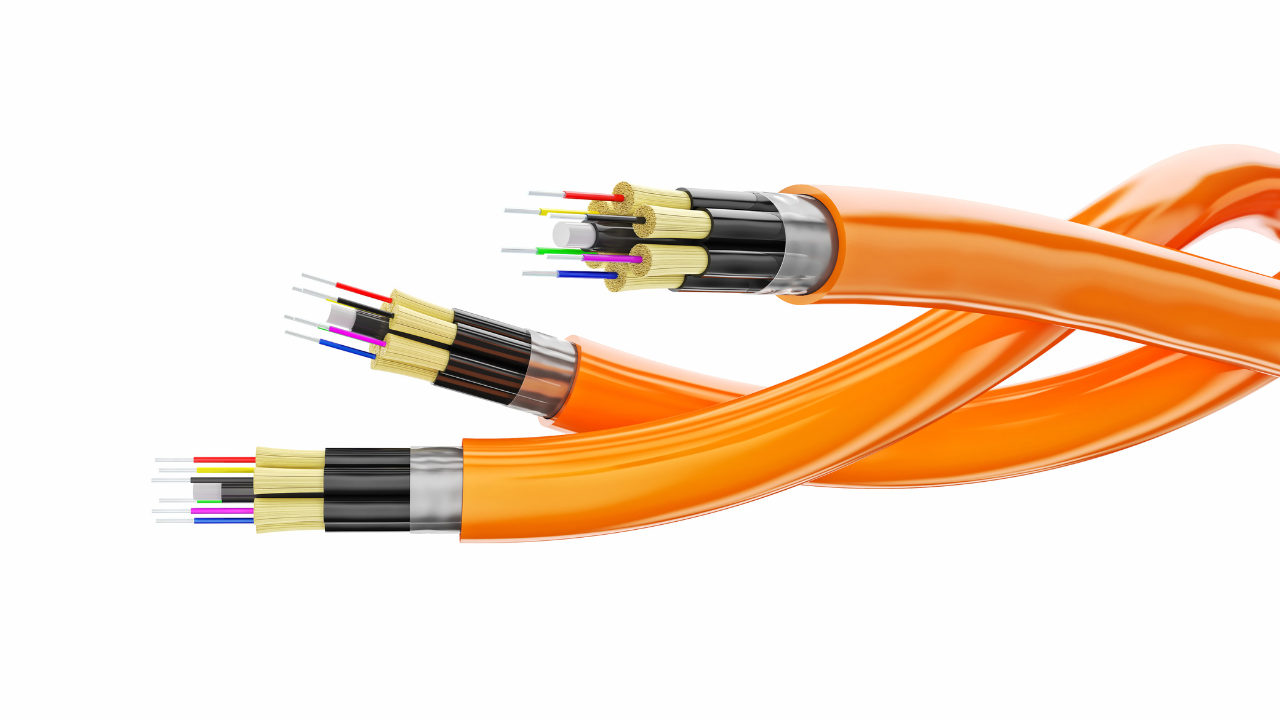

A Fiber Optic Cable is a network cable with improved performance and bandwidth for data transfer. In addition, fiber optic cables are more reliable than standard metal conductors. As a result, cable manufacturers are producing these cables for commercial purposes.

When it comes to optical fiber cable manufacturers, “Usha Martin” is one of the most popular brands in the market as they are equipped with global standard manufacturing units to produce high-quality optical fiber cables. Usha Martin is one of the world’s leading cable suppliers.

Fiber optic cable is suitable for the transfer of information using the medium of light. These cables consist of thin, transparent glass fiber rods. The fibers have three layers; the first layer is called the core, which is comparatively very smaller in diameter than the average hair diameter. Cladding is the second layer, which is constructed with a different refractive index as compared to the fiber core. Cladded fiber forms the third layer, i.e., acrylate coating. These fibers are cascaded in polymeric tubes. The multiple tubes are wrapped around to strengthen the members. The complete unit is coated/encapsulated in a sheathed/jacketed compound.

Types of Optical Fiber:

1. Single-Mode Fiber: Single-mode fiber optic cables are used for long-distance signal transmission.

2. Multimode Fiber: Multi-mode fiber optic cables are manufactured with a wide diameter and larger cores. These cables are used for shorter data transmissions.

Types of Optical Fiber Cable

There are generally four types of optical fiber cables. The following cables are different as per their build type and usage:

1. CATV Cable: Used for cable antenna TV signal transmission.

2. Multi-Loose Tube OFC: These cables are manufactured with multiple tubes for branch communication.

3. Armoured OFC: Armoured cable is used for direct burial or trench deployment applications.

4. ADSS OFC: All Dielectric Self-Supporting Optical Fiber Cable is used for hanging applications, exhibiting very strong pulling strength.

The Benefits of Optical Fiber Cable

Fiber optic cable has many benefits, and a few of them are explained below:

1. Bandwidth & data transfer: Fiber optic cables are the best for data transfer and efficient transmission of signals.

2. High Speed: These cables use light pulses for data transfer and provide a higher speed of transmission.

3. Distance: Fiber optic cable can cover a very long distance as compared to copper cables. These cables offer less optical or transmission loss in signals.

4. Interference: Fiber optic cables offer high protection against interference compared to traditional metal wires. It has the capability to boost data transfer for much longer distances with safety.

5. Safety & reliability: Optical fiber cables are safe, reliable, and comparatively much lighter in weight. These cables are sturdier and come with a weatherproof coating.

Why Choose Usha Martin?

Usha Martin is one of the leading fiber optic cable manufacturers and exporters. With over 6 decades of expertise, the company offers the best solutions when it comes to optical fiber for faster communication and low signal loss.

At Usha Martin, low-risk and high-flexibility optical fiber cables are manufactured. Our superior quality optical fiber cable ensures high data security and efficient transmission.

We have a wide range of offerings: 1F to 48 F Uni-tube construction, 2F to 432 multi-tube construction, and Micro-duct cable. In addition to these, we manufacture hybrid cables and composite cables. We also produce underground and FTTH optical fiber cables.

Get the complete range of FTTH LSZH Sheath cables, FTTH Drop cables, and micro duct cables. Apart from optical fiber cables, we also produce jelly-filled copper cables, aerial copper cables, and duct copper cables, ranging from 5 pairs to 2400 pairs of cables. Usha Martin Cables also manufactures FRP (Fiber Reinforced Plastic) rods ranging from 0.5 to 3.5 mm in diameter. To know more about fiber optic cables, connect with Usha Martin experts, and get more information on our exclusive range of fiber optic cables.

There is no denying that wire ropes are one of the most used materials in the industrial landscape. According to Statista, in 2020 itself, the production volume of steel wire ropes in Japan amounted to approximately 240.32 thousand tons. Their necessity is evident, and the wire rope sling manufacturers are increasingly deploying their solutions in marine environments or for rigging purposes. However, as wire ropes face considerable loads, they suffer massive mechanical damage.

As suggested by the leading steel wire rope manufacturers, some well-known reasons for wire rope failure are corrosion, excess deterioration, improper usage, and lack of maintenance resulting in reduced safety, increased replacement costs, and early discard. Do you want to know the professional ways steel wire rope manufacturers inspect wire ropes? Then here's a guide for you!

All wire ropes must be inspected visually on daily basis before starting the operation. This safety guideline can ensure maximum security. Although it's daunting to determine the exact service span of the ropes, close analysis on a more frequent basis can help get a more precise estimation of their predictive life cycle. Also, note that calculating the precise times when the ropes have been in use during the mooring/tidal conditions, load pressures, etc., can be the answer. A competent person shall carry out an overall, thorough periodical inspection of the wire rope.

Well, you can assess the wire rope condition by standard inspection. Look for signs of:

The rag and visual method

You can use the rag-and-visual process to check for any external damage. All you need to do is grab the rope lightly with a rag or cotton cloth. Then move the rag along the wire, and if there are any broken wires, they will stick out and snag on the rag. If the cloth catches broken wires, you can stop and assess the rope visually. Also, make sure to visually inspect the wire without any rag because some wire breaks don't stick out.

Measure the rope diameter vividly

Measure the diameter of the rope and compare the diameter with the original values. When the measurements are different, the change implies internal or external rope conditions.

Check for abrasions

When a steel wire rope passes over the drum and sheaves or any other metallic equipment component, abrasion takes place. Hence, it is important that all components must be in proper working order and of the appropriate diameter for the rope. A badly corrugated or worn-out sheave or drum will significantly damage a new rope, resulting in premature rope replacement.

In addition, try to look for corrosion, pitting, abrasions, end fitting conditions, wire breakage (if any), and lubrication inside the rope. Wire rope should be inspected to check for any abnormality like External damage, Kink, Strand looseness, Core protrusion, or Bird-caging.

It is always recommended to maintain the inspection records to assess the rope condition in the next inspection schedule.

Word of caution

While sometimes the damage can be easily identified on the surface, in other cases, the fracture might occur inside the wires. Therefore, ensure that the ropes are maintained, manufactured, and inspected by competent professionals. Searching for the best wire rope sling manufacturers and inspecting company that focuses stringently on quality checks? Usha Martin can be your one-stop solution!

The wire rope market has witnessed immense growth because of the rising demands in the manufacturing sector and growth in infrastructure. Moreover, the rising number of projects related to drilling from ores, coal mining, and oil exploration brings a major market chance for the pioneer players operating in the steel wire rope market. The global steel wire rope market is estimated to see high growth in the coming period. With so many companies competing against one another, one company that deserves your attention worldwide now is Usha Martin.

What makes Usha Martin a leading Wire rope manufacturer and supplier globally?

Usha Martin has made its own place in the international market and has stood tall for the past 60 years. The company is one of the largest wire rope producers in the world. Decked with state-of-the-art technologies and technically advanced infrastructural facilities, it uses the highest-capacity machines to produce steel wire ropes, mining rope, elevator wire rope, fishing rope, structural rope, crane wire ropes, wire rope sling, and optical fiber cables to name a few. Besides producing wires, it also manufactures a wide variety of LRPC strands, including polymer-coated bonded & unbonded LRPC strands, which find application in various infrastructure, construction, and bridge projects.

The company delivers a wide range of value-added products and customized solutions to meet customers' specific needs. It offers services in varied sectors ranging from mining, crane, infrastructure, elevator, oil, and offshore. Its global clients are a testimony to its expertise in manufacturing top-notch products. Usha Martin has become one of the leading global players by offering comprehensive solutions using modern technologies and delivering sustainable growth opportunities to its customers.

Why do industries across the world partner with Usha Martin?

There are several benefits of working with Usha Martin. Some of them are given below:

● Total solution provider: Usha Martin offers complete solutions under one roof when it comes to wire rope manufacturing, rigging services, installation, inspection, prestressing solutions, NDT services, etc. The company offers tailor-made products with value-added services to meet specific client requirements. The manufacturing plants and service centers have world-class rigging facilities, providing turnkey solutions, including socketing, cutting, coiling, spooling services, etc. From production and supply to installation, the company offers all turnkey services to its customers worldwide.

● Global service network: Usha Martin has a robust, well-established network set up globally. All the service centers are decked with best-in-class rigging facilities to meet the specific demands of clients. The company enjoys support from a broad network of dealers worldwide, which are well equipped with in-house assembly and testing facilities to offer tailor-made products to suit different working conditions and ensure smooth delivery of products at the client's site.

● Global R&D: When it comes to innovation and development, the company offers several innovative solutions for different sectors taking every initiative to meet their technical needs, focusing on designing top-quality wire ropes for critical applications to suit adverse working conditions. The Global Design Centre provides support to the group's manufacturing units and project management teams while leading technical guidance towards rope design, product improvement, and R&D activities.

● Superior Performance: The products manufactured at Usha Martin deliver longer service life and ensure the utmost safety, keeping quality their major concern. With six decades of experience, the company uses state-of-the-art technologies. Processes undergo stringent quality testing measures at every stage of operation to produce high-quality wire ropes that meet global standards.

● Global Accreditations: As Usha Martin pays utmost attention to its quality, it has several international accreditations to its name. The company's quality management system is certified by ISO 9001 and ISO 14001. It is also accredited by many global manufacturing assessments, including ABS, Lloyds, DNV-GL, SNI, Australian Certification Authority for Reinforcing & Infrastructure Steel, etc.

● Wide product range: Excelling in all the products it has to its name, Usha Martin offers a wide range of high-performance wire ropes, LRPC Strands, wires, prestressing accessories, and cables in the best quality to suit all critical environments for different applications across the industry.

● After-Sales and Service: What makes Usha Martin stand out from the crowd is its after-sale services. The company has a robust network of service centers located worldwide. They work in the best efforts with their clients to extract the optimum performance of their products. From installation to an inspection of the wire ropes in different applications, it offers complete after-sales services to its customers. The company also offers customized training programs for its clients.

Usha Martin has been one of the best wire rope suppliers to several industries globally for six decades. The company follows innovative product development and unique manufacturing techniques to offer a wide range of high-quality wire ropes, wires, and strands.

Some of its most demanded products are:

● Steel wire rope: The company enjoys as one of the top players in producing the widest range of wire rope products globally. These ropes service different applications across various industrial segments.

● Oil and offshore rope: The Titan Oil field rope from Usha Martin is known for its superior strength and power. Manufacturing using top-notch technology, they offer a great strength-to-weight ratio.

● Crane rope: Crane wire ropes from Usha Martin offer high performance, longer service life, and less downtime, increasing operational efficiency even in harsh working conditions.

● Mining rope: Usha Martin mining ropes are designed to perform in harsh mining conditions in both surface and underground mining, helping the users accomplish lower downtime, higher life, and reduced maintenance cost.

● Structural rope: Usha Martin produces a wide range of high-quality structural ropes for critical projects and installations around the world. It offers superior quality pre-stretched locked coil bridge ropes and requisite end fittings in a ready-to-install condition.

● Conveyor Cord: Usha Martin produces high-quality conveyor cords, offering superior strength for use in belt conveyors for material handling industries.

● Engineering Rope: The company also produces different types of wire ropes suitable for general purposes like guyline, boring application, etc.

Conclusion

So, with years of experience and tradition in offering a wide range of products and an ideal customer service package, Usha Martin continues to rule the major businesses to date. Its varied range of wires, wire ropes, LRPC strands, and cables find application in construction, mining, elevator, automobile, oil & gas, fishing, telecom, and many more. The company has its reach in all the major markets and is one of the largest wire rope manufacturers globally, offering all the services under one roof. Connect with us to get more information on our products and services. We are here to help you.

Wire ropes have numerous applications in the offshore industries due to their massive strength and durability. Offshore wire ropes, slings, and other rigging equipment handle heavy loads in daily operation. In addition, they are constantly exposed to adverse weather conditions, saline ocean water, etc. Like any machinery and equipment, wire ropes and slings also need proper care and maintenance to ensure their longevity and strength.

Seizing or cutting wire ropes is vital to deploy them in suitable applications. Moreover, seizing them appropriately is a must to ensure safe and efficient operations. Improper or inadequate seized ends of ropes can be colossal trouble ahead since it can cause flattening of ropes and uneven distribution of load, making it susceptible to premature wear and tear.

Since wire ropes are primarily used for heavy equipment lifting, you must conduct regular inspections. Any carelessness or lack of maintenance can cause the ropes to break, resulting in huge losses, accidents, and even fatal injuries. If any change or issue in the rope is noticed during inspection, it must be immediately reported.

Although most wire ropes come with original lubrication, it often gets removed due to constant friction and adverse conditions. The wire rope is constantly exposed to environmental elements if the lubrication isn't replenished. Thus, it is advised to maintain proper lubrication to protect the wires and the core from dust, debris, unwanted friction, and corrosion.

Are you installing offshore wire ropes on your own? You better leave it to professionals unless you have the proper training. Professional wire rope installers are well-trained in considering every little detail during installation. For example, they use suitable tools like calipers to calculate the rope's nominal diameter to see if it is compatible with the equipment.

If you are storing the wire ropes, ensure they are in dry, covered, and well-ventilated conditions. The best practices are keeping them away from moisture, dust, steam, chemicals, and adverse weather conditions.

Wire ropes are designed accordingly to suit the most demanding and critical working conditions in the oil & gas industry. For that, you must begin with getting high-quality wire ropes. Usha Martin is the ultimate destination for international-standard oil & offshore wire ropes, mooring rope, sand line, bull line, slings, and essential rigging services. All their products undergo vigorous quality testing, making them a globally renowned manufacturer and supplier of high-performance wire ropes. It's a one-stop solution company, offering heavy spooling services, proof testing, inspection facilities, and full rigging shop services covering pressed terminations and wire rope socketing.

What are wire ropes made of?

Wire ropes are typically manufactured from high carbon steel wires, stranded together to form a thick and strong rope.

What are some offshore applications of wire ropes?

Wire ropes are widely used in drilling, hoisting, rigging, offshore mooring, anchoring, towing, etc.

Why is rope oil necessary?

Rope oil or lubricants protect the wire ropes from wearing off early since it creates a protective layer against dust, water, salt, chemicals, etc.

Does the best wire rope supplier provide rigging equipment?

Yes, they are global-standard manufacturers of wire ropes, slings, marine mooring systems, and complete rigging solutions.

Does your business largely depend on wire ropes? The steel ropes used in heavy-duty applications are specially designed with the required specifications to meet the requirements of the most demanding applications. A typical wire rope is made of four components—wire, strand, core, and rope. Apart from these, you might come across many other terms while dealing with wire ropes in day-to-day industrial activities. Read further to learn about some of the most common wire rope terminologies.

Steel wire ropes have been a revolutionary invention. Its strength, reliability, and versatility make it ideal across a wide range of industries. From oil rigging to cargo lifting, they can withstand many heavy-duty applications. If you are also searching for the best steel wire rope suppliers, then Usha Martin is the one to trust. We are renowned steel wire manufacturers in India for delivering high-quality wire ropes, LRPC strands, pre-stressing solutions, and optical fiber cables. Get in touch with us to get industry-leading wires and cables today.