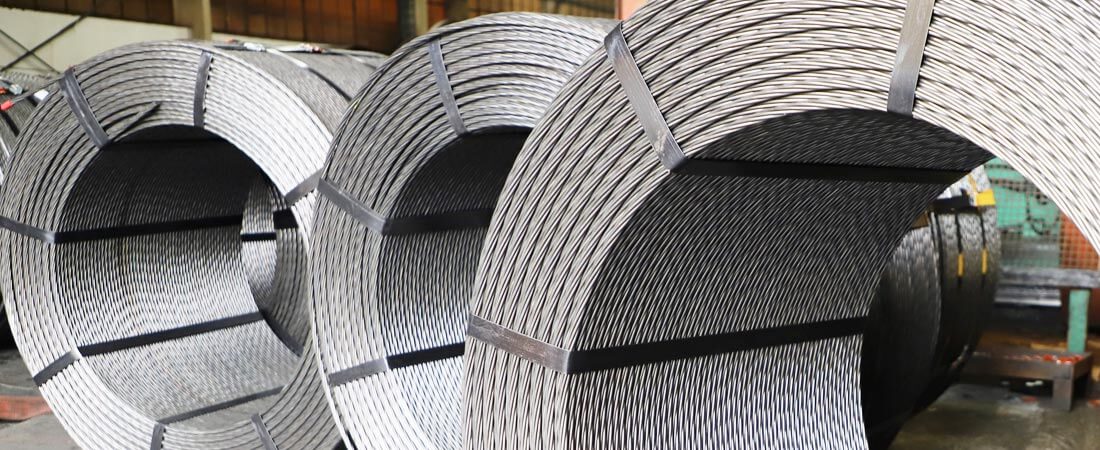

Usha Martin's continued investment in technology and equipment consistently developed products to the highest quality standards. With years of engineering excellence, many new varieties of LRPC strands were added to the product range to keep pace with new concepts and applications.

Usha Martin's product basket encompasses a comprehensive range of LRPC strands, namely:

Usha Martin, one of the most preferred LRPC Strands Manufacturers and Suppliers, offers strands of all available sizes and grades that can be polymer sheathed and galvanized in conformance to major national and international specifications.

The Compacted LRPC Strands Manufacturer uses a high-pressure compaction process to produce Round Strands. For a given diameter, the Steel content, as well as the Strength, increases drastically.

Usha Martin has the state-of-the-art technology to produce and supply Indented LRPC Strands. The Strand is manufactured using individually Indented wires, which enhance the Bonding/adhesion of the steel with the concrete and thus help the structure to become more Monolithic.

This LRPC Strand may be bright or galvanized depending upon the environment, is coated with a corrosion resistant/water repellent – high-temperature grease to fill the interstices between the wires, followed by a co-extrusion of a UV stabilized polymer layer with a thickness (min 0.5 mm, max as per customer requirement).

Usha Martin's un-bonded PE coated LRPC strands have excellent durability and provide perfect protection against corrosion due to tri - complementary nested barriers formed by galvanization followed by anti-corrosion, water repellent - grease/wax coating in the interstices, and finally, the UV stabilized polymer sheath, extruded onto the LRPC Strand. This particular arrangement also enables monitoring of strands by replacing a post-tensioned strand at regular intervals.

Bonding implies adhesion of the polymer sheath with the steel surface of the LRPC Strand. Bonded PE coated LRPC strands exhibit a strong bonding strength and conform to the requirements of the customers. The state-of-art of sheathing lines and stringent control parameters during manufacturing, particularly with regard to the diametrical concentricity of sheathing, consents bridge designers to bundle Usha Martin strands with confidence.

Usha Martin’s bonded LRPC strands has an excellent durability and provides perfect protection against corrosion due to tri-complementary nested barriers formed by galvanization followed by anti-corrosion wax coating in the interstices and finally the UV stabilized polymer sheath.

Usha Martin Ltd.

Wire & Wire Rope Unit,

Tatisilwai, Ranchi,

Jharkhand - 835103.