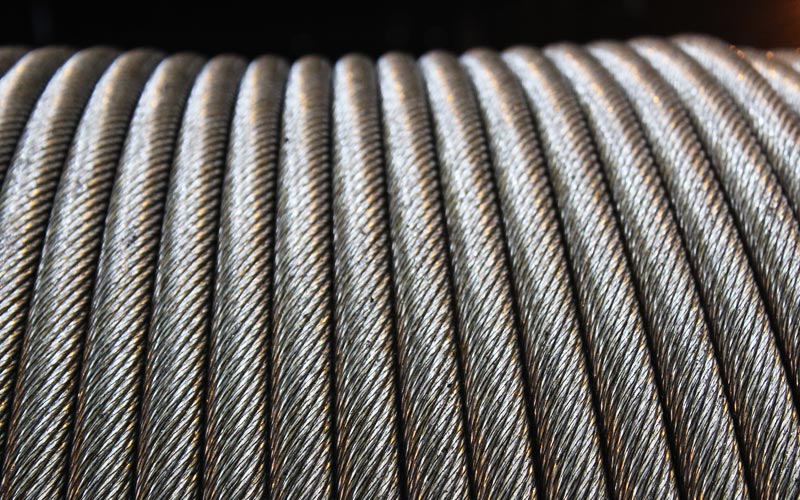

The global success of Usha Martin’s crane rope is based on an uncompromising commitment to quality. Our wire rope for cranes are designed to provide longer life, less downtime, and superior resistance to bending fatigue for lifting applications under adverse working conditions. The company’s quality management system is certified per standard ISO 9001: 2015, along with manufacturing assessment certifications from ABS, DNV-GL, and Lloyds. Crane ropes supplied by Usha Martin and its group companies are supported by an extensive global network, offering expert advice to both crane manufacturers and end users.

With six decades of excellence in manufacturing specialty steel wire ropes for cranes, we have developed next-generation crane ropes for different applications to meet the specific needs of customers. These cover all types of wire rope for cranes, including specially designed compacted ropes with plastic-impregnated cores and rotation-resistant ropes. All steel wire ropes undergo stringent quality testing procedures. We offer a wide variety of hoist ropes to suit the needs of different industrial applications.

Usha Martin’s Crane rope finds application in the following areas:

Size Range:

8 mm to 127 mm (0.3149 inches to 5 inches).

Rope Processing For Use:

Installation of crane ropes:

Inspection:

Post Inspection Services:

Technical Training & Webinar:

The company is committed to preserving the legacy of quality worldwide. It continues to harness its global presence to deliver the best products and solutions for its customers worldwide.