Usha Martin’s specially designed high-performance wire ropes are one of the most crucial components in heavy-duty cranes, without which the cranes can’t function at all. Our wire rope ensures a longer operational life and minimises downtime costs. Proper storage, installation, maintenance, lubrication, and discard of wire rope needs to be carried out as per international standard ISO 4309 to extract the maximum life from our products.

Proper Storage of wire ropes

Storage

Wire rope lubrication

A wire rope is a piece of machinery with many moving parts (wires-strands) and as such it is subjected to internal and external friction causing wear and corrosion.

Suitable lubricants are applied during the manufacturing of the core, the strands, and finally the finished ropes. The service lubricant should be compatible with the original lubricant used by the wire rope company.

A good lubricant must have the following properties:

Rope lubrication during manufacturing:

Basic discard criteria of wire ropes

Broken wires

Increase in rope diameter: This characteristic is often related to a change in the condition of the core, such as a fibre core swelling up due to the absorption of moisture or the accumulation of corrosion debris within the rope.

If the rope diameter increases by 5 % or more in a rope with a steel core or 10 % or more in a rope with fibre core during service, the reason for this shall be investigated and consideration is given to discarding the rope.

Decrease in rope diameter: A decrease in rope diameter can result from a number of factors, one of which is external wear. Usually results from contact with sheaves or drums or from the pressure of rope on the rope, as would be expected at the cross-over zones as the rope traverses the drum. More pronounced amounts of wear are usually found in those sections of rope which are in contact with the grooves of sheaves and drums when the load is being accelerated or decelerated. A lack of lubrication and the presence of abrasive dust can also affect the rate of wear. In addition to the obvious visible mode of deterioration described above, the rope can also decrease as a result of one or a number of internal mechanisms, such as:

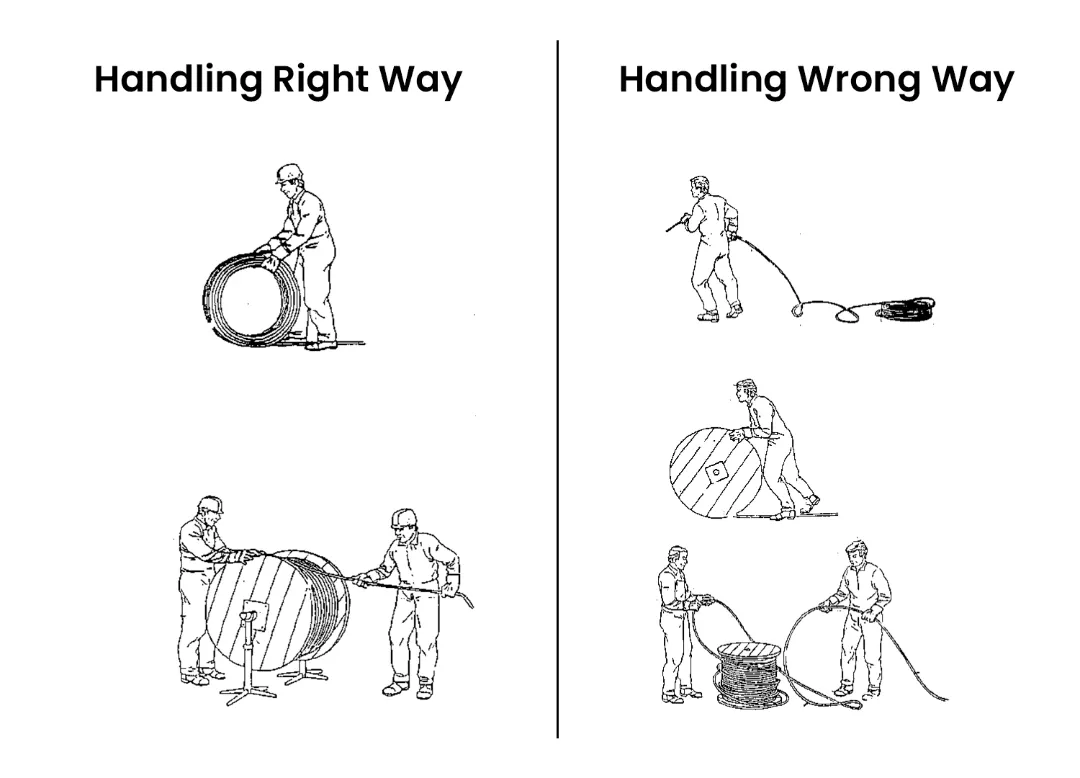

Conclusion: We at Usha Martin are committed to working together with our customers to extract the optimum life cycle from our wire ropes. Therefore, proper storage, handling & installation of wire rope is crucial. Thus, being one of the leading wire rope manufacturers, we follow international standards as per ISO 4309 in helping our end-users to achieve maximum performance from our products.