Usha ISMAL division is the pioneer and leader in offering complete prestressing solutions since its inception in 1965. We started manufacturing prestressing equipment & materials in collaboration with CCL Systems Ltd. of Leeds, U.K. (presently known as CCL Stressing Systems Ltd). Usha ISMAL has over five decades of rich experience in manufacturing and supplying prestressing machines & accessories, backed up by the expert installation team for pre-tensioning and post-tensioning jobs.

With profound expertise in offering pre-tensioning & post-tensioning solutions, Usha ISMAL serves various heavy civil engineering construction applications like bridges, elevated structures, metros, flyovers, silos, nuclear reactors, very high capacity water tanks in deserts, dams, rock & ground anchoring, etc. across the globe. Usha Ismal's complete prestressing solutions include system design, supply of different LRPC strands, anchorage accessories & necessary Prestressing Equipment at our state of art manufacturing facilities, supported by an expert execution team for installation. Our factory at Ranchi has in-house heat treatment and electro-plating facilities. The manufacturing facility has been accredited by ISO 9001 quality system to ensure the highest grade of quality products and services.

Usha Martin’s continued investment in technology and equipment consistently developed products to the highest quality standards. With years of engineering excellence, many new varieties of LRPC strands were added in the product range to keep pace with new concepts and applications.

Usha Martin product basket encompasses a comprehensive range of LRPC strands, namely:

LRPC strands of all available sizes and grades can be polymer sheathed and galvanised in conformance to major national and international specification.

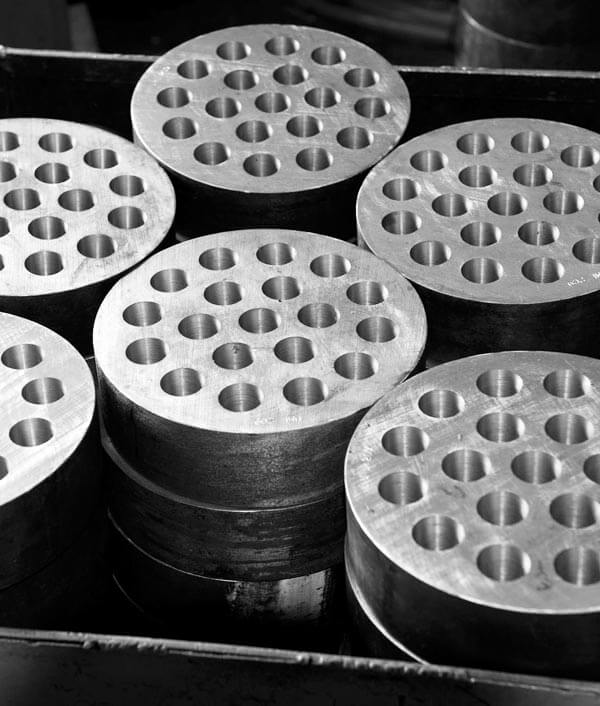

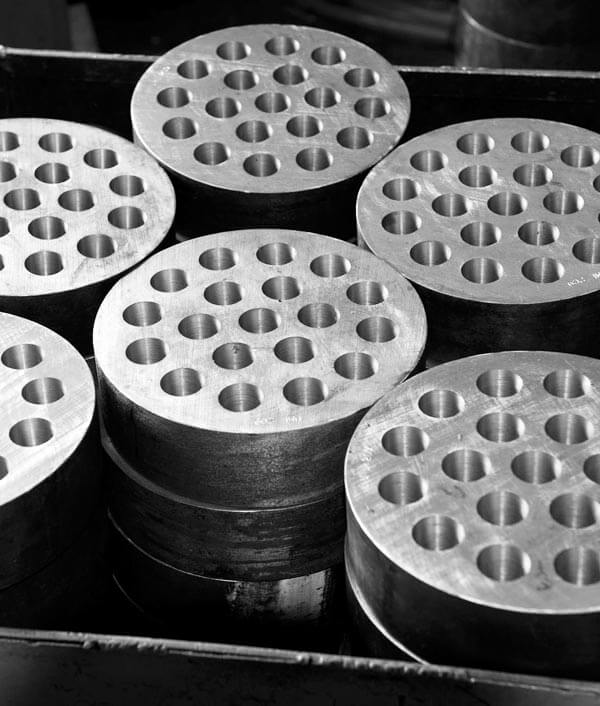

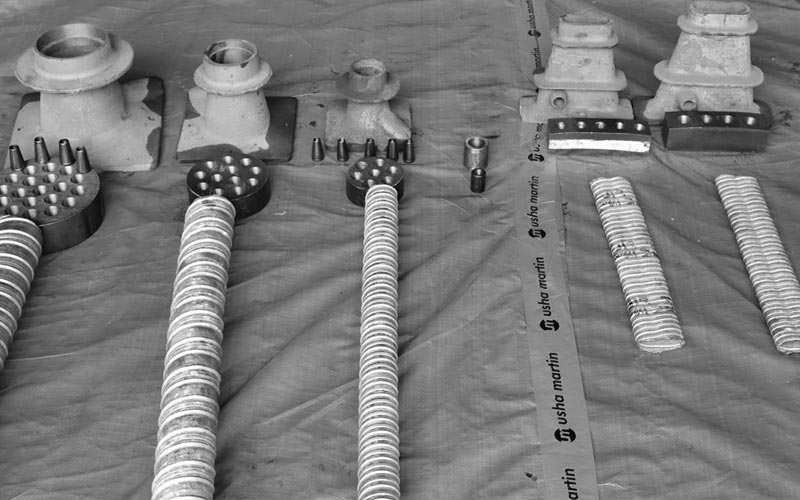

We being the pioneer in pre-stressing activities, have the necessary manufacturing infrastructure for supplying all types of components required in pre-stressing operation. Our anchorages are suitable for both round & flat type tendons. The anchorage set, comprising of Tube Unit, Sheathing Pipe, Bearing Plate and Ancharite Wedges are used in post-tensioning jobs; Wedge-grips and Barrels are used in pre-tensioning, both are well accepted world-wide for best in class quality.

Our anchorages are suitable for :

Round Tendon Systems - required in heavy civil structures like Metros, Flyovers, Bridges, Silos etc.

Flat Tendon Systems – required in PSC Slab Projects like Building Projects.

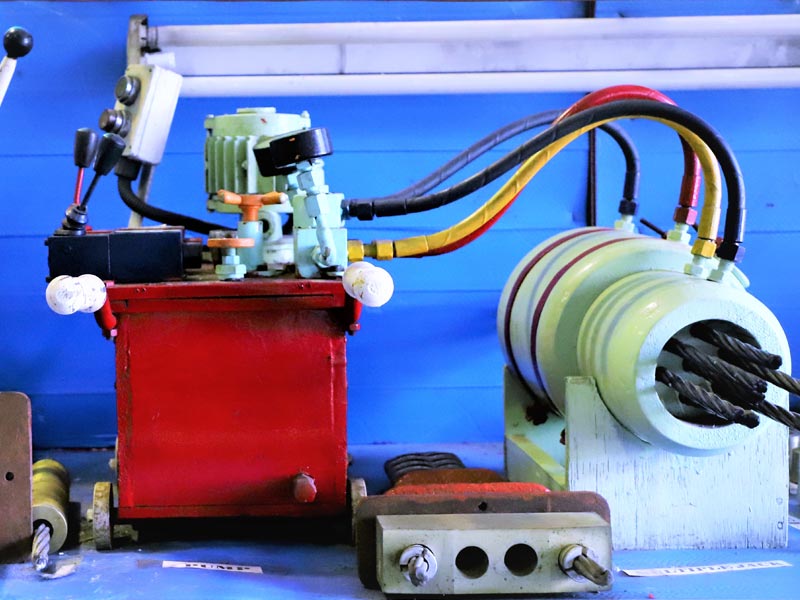

Pre-stressing activity call for deployment of various hydraulic and pneumatic equipment at the project site which have to perform with great accuracy and time bound performance.

We manufacture various Hydraulic Equipment:

Hydraulic Jacks

Powerpacks

Grout Pump & Grouting Agitator

Pre-stressing activities requires supply of anchorages, LRPC strand and on-site stressing services. Pre-stressing encompasses pre-positioning & post-positioning both internal and external. Usha Martin has a wide spread set-up for undertaking all types of pre-stressing jobs. Pre-stressing activities generally comprises of profiling pre-stressing tendon at the time of casting, stressing on achieving the strength of cast structure and grouting to remove the void spaces, thus making the tendon integral to the cast structure.

All the above activities are executed by UML expert site personnel using sophisticated hydraulic and pneumatic equipment, which are also manufactured in our state-of-art manufacturing plant located at Ranchi in India.

UML executed various pre-stressing activities for numerous applications like Buildings, Nuclear Reactor, Elevated Structure including Cement and Clinker Silos, Metro projects, Extra dosed bridges, Gigantic water tanks on desert area, Ground anchoring in Dams, Rock fall arrester, Soil Stabilization, High speed Railway projects and RRTS projects.

Usha Martin service team has a vast experience to execute all pre-stressing activities in many of such prestigious projects both in India and abroad.

We have the following testing facilities at our Ranchi plant both for pre-stressing materials and LRPC strand:

Both the above tests are conducted as per FIP 1993 and BS 4447:1973.

Special quality system testing is undertaken to manufacture high quality LRPC strands, which are best in its class.

Relaxation Testing Machine

Relaxation Testing Machine Breaking Load Testing Machine

Breaking Load Testing Machine