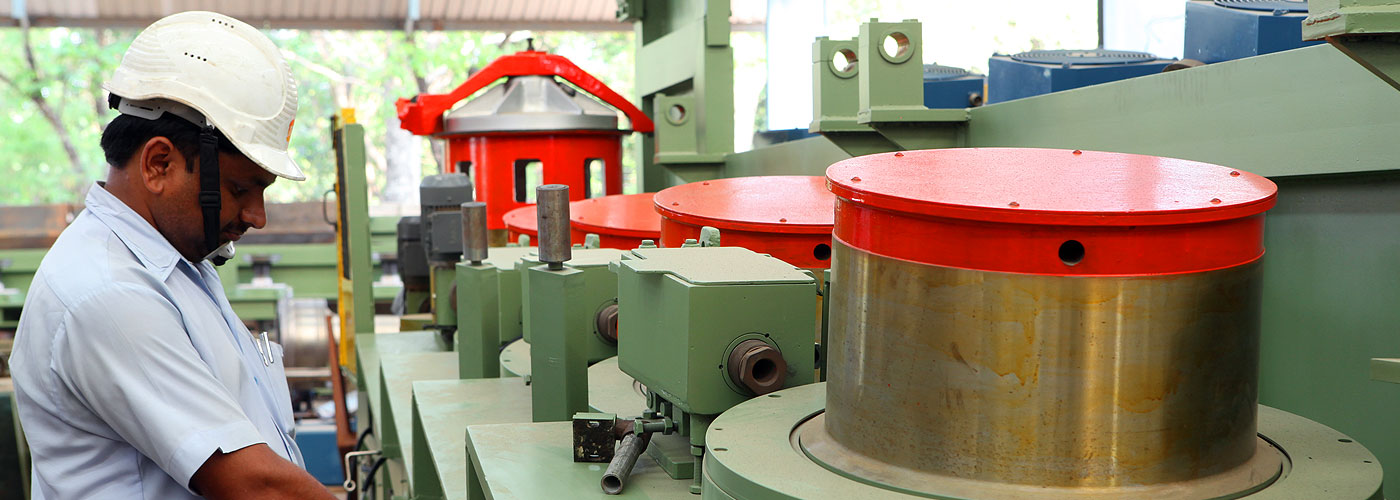

The Ranchi based facility of Usha Martins’ is one of the world’s largest wire rope manufacturing units. Spread across an area of more than 100 acres, this facility is also the company’s first manufacturing facility that was set up in 1961.

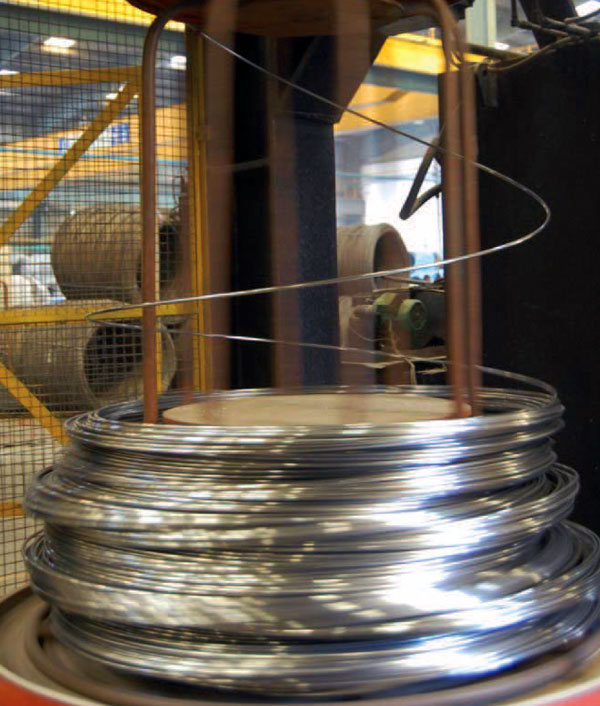

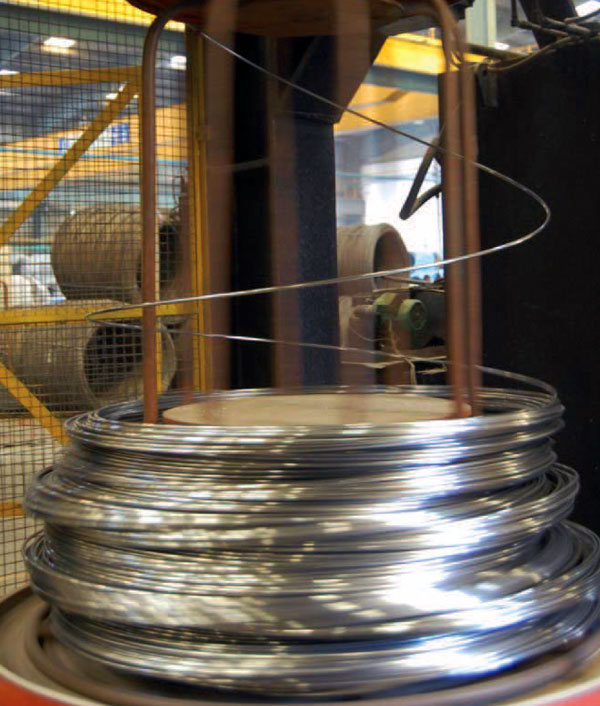

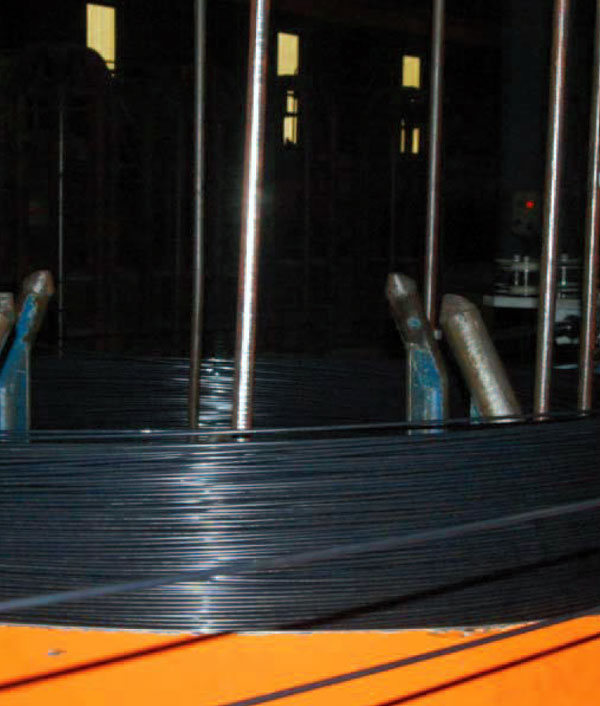

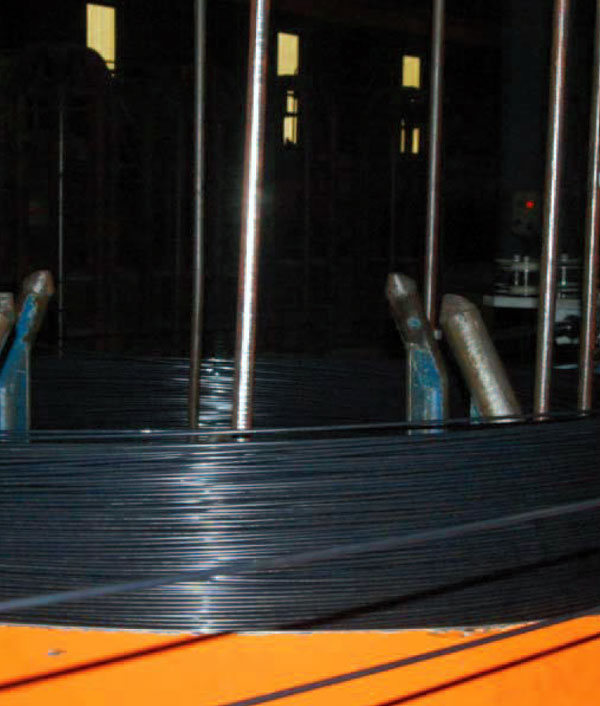

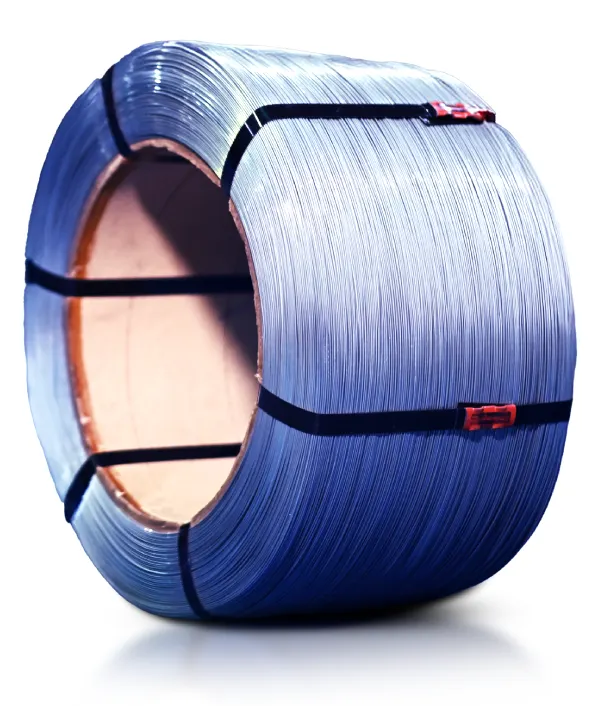

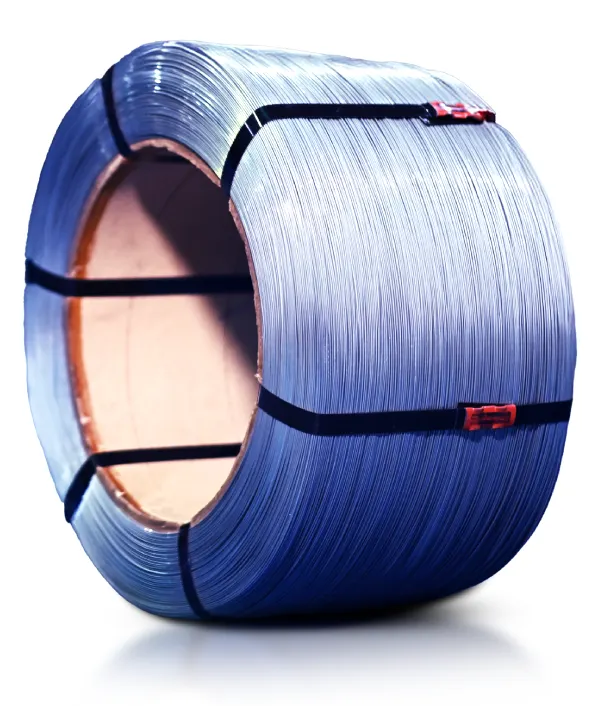

This facility is equipped with state-of-the-art, high capacity machines to manufacture world-class products. Special grade wire rods, selected after stringent quality checks, are processed through modern pickling, patenting and galvanizing facilities. This is then followed by wire drawing, stranding and closing to produce high performance wires, strands and wire ropes suitable for multiple applications.

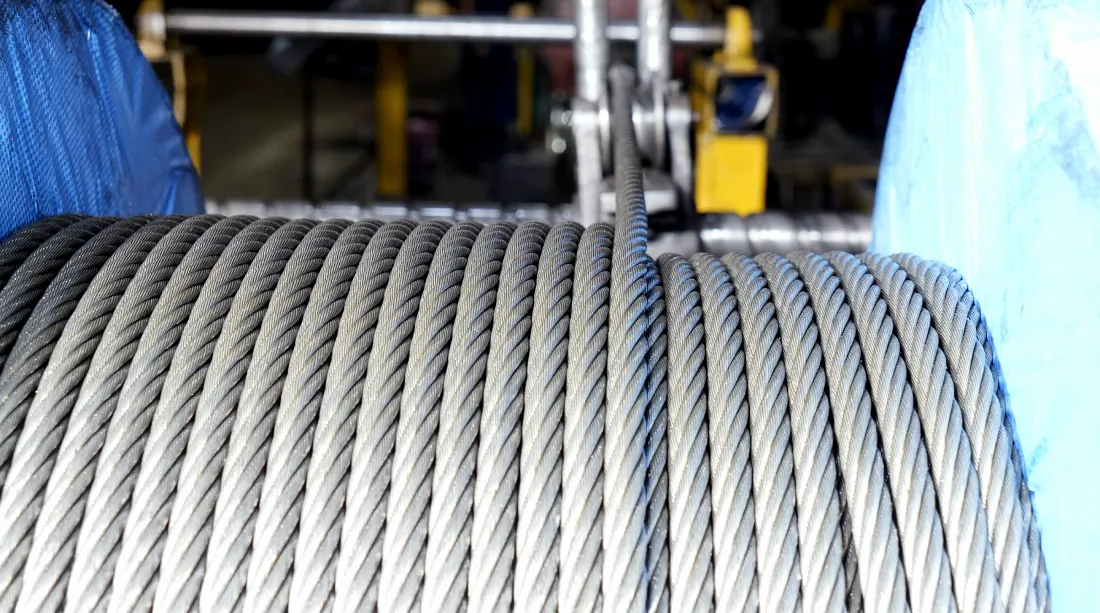

The wire ropes manufactured in this plant ranges between 1.5 mm to 155 mm in diameter and are available in various tensile grades, from 1370 to 2160 N/mm2 tensile. The high quality wire ropes produced here find application in various sectors like Oil & Offshore, Mining, Crane, Elevator, Aerial Ropeway, Construction, Fishing and many more.

Other than wire ropes, this unit also manufactures LRPC strands, customized for diverse applications in infrastructural developments, renewable energy installations, construction and maintenance of bridges etc.

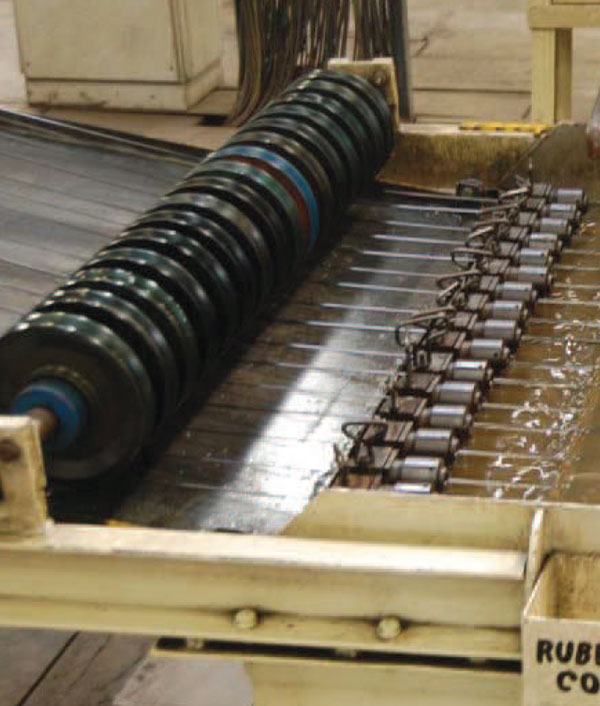

Usha Martin also has an excellent track record in the manufacturing & supply of pre-stressing machines & accessories, backed by expert installation teams for the pre-stressing job. The facility at Ranchi also has an additional set-up for manufacturing high quality conveyor cords and machineries.

The global success of Usha Martin crane rope is based on an uncompromising commitment to quality. The crane ropes are designed to provide longer life, less downtime and superior resistance to bending fatigue for lifting applications under adverse working conditions. Our quality management system has been certified as per standard ISO 9001: 2015, along with manufacturing assessment certifications from ABS, DNV-GL and Lloyds. Usha Martin crane ropes are supported by an extensive global network, which can offer expert advice to both crane manufacturers and end users.

As a global manufacturer of high quality, high performance wire ropes, we have always focussed to design products that satisfy most demanding critical requirements in the oil & gas industry.

With six decades of expertise and manufacturing excellence, we offer the best products and solutions to our customers, supported by our robust technical service network spread across the world.

We offer a complete range of high quality elevator ropes, ensuring superior performance and high order of safety requirements in the elevator industry. Manufactured under stringent norms and advanced state-of-the-art technology, our elevator ropes are designed with close dimensional tolerances to provide jerk free movement of elevator.

When it comes to critical operations in mining, the global mining companies trust mining ropes from Usha Martin. Our wire ropes are designed to perform in harsh mining conditions in both surface and underground mining ropes. No matter how critical your application is, Usha Martin's expertise in design and manufacturing of mining rope is always there to meet your requirement. All mining ropes undergo rigorous testing procedures to meet the technical specifications, as per our customer demand for today’s challenging working conditions.

A major deteriorating force for the fishing rope is the corrosion factor in the marine environment. Larger outer wire diameter, superior quality of galvanization, and application of high quality of lubricant to check corrosion considerably, together extend rope life of Usha Martin Fishing Ropes. A state of the art plastication line has made Usha Martin’s ropes widely popular in the industry due to multiple benefits to the users from plastication.

We supply high quality ropes to various industries for general engineering purpose in different applications. One of the most widely used construction is 6x36 (steel/fibre) core.

Usha Martin Aerial ropes are known for a high order of safety, low maintenance, long life, excellent quality, and high strength.

Our product offerings include

Size Range:

12 mm to 40 mm (0.472 inch to 1.5748 inch)

Some of the prestigious projects around the world like Vidyasagar Setu in Calcutta, Lions Gate Bridge in Vancouver, and TV Towers at UAE today are a few manifestations of Usha Martin’s expertise in structural systems. Usha Martin has capability to provide bridge cables, prestretched & protected from corrosion, along with requisite end fittings in a ready-to-install condition.

Applications of structural system from Usha Martin include:

Usha Martin’s continued investment in technology and equipment consistently developed products to the highest quality standards. With years of engineering excellence, many new varieties of LRPC strands were added in the product range to keep pace with new concepts and applications.

Usha ISMAL division is the pioneer and leader in offering complete pre-stressing solutions, since inception in 1965. ISMAL started manufacturing pre-stressing equipment & materials in collaboration with CCL Systems Ltd. Of Leeds, U.K. (presently known as CCL Stressing Systems Ltd). Usha ISMAL has over five decades of rich experience in manufacturing and supply of pre-stressing machines & accessories, backed up by the expert installation team for pre-tensioning and post-tensioning job.

We are leading manufacturer & exporter of Optical Fiber Cable since year 2000. We believe in continual improvement in our product by offering best solutions based on Faster Communications, Less Expensive, Low signal loss, Usage of less energy, Low risk of injury, Flexible, Smaller in dimensions, High data carrying capacity, High security & Light weight cable.

The facility has been accredited with ABS Certification for Manufacturing & Design Assessment, API Certificate, ISO 9001, ISO 14001, DNV, Lloyds and NABL certification for Mechanical & Chemical Test.

The company’s Quality Management System ensures that the materials undergo stringent quality checks at every stage of the manufacturing process.

Usha Martin offers a wide range of high value wire ropes with special designs to meet specific needs of clients for critical applications under challenging conditions.

The unit has world class rigging facilities, and is well equipped to offer customized solutions, including socketing, cutting, coiling, spooling, pre-stressing accessories and turkey solutions.

The company also offers technical services, which includes installation and inspection of wire ropes for different applications, including NDT services.

Usha Martin also conducts customized technical training programs for end-users and customers.

Usha Martin Ltd.

Wire & Wire Rope Unit,

Tatisilwai, Ranchi,

Jharkhand - 835103.

The Usha ISMAL division has been a pioneer and leader in offering complete pre-stressing solutions since its inception in 1965. ISMAL started manufacturing pre-stressing equipment & materials in collaboration with CCL Systems Ltd. of Leeds, U.K. (presently known as CCL Stressing Systems Ltd). Usha ISMAL has over five decades of rich experience in manufacturing and supply of pre-stressing machines & accessories, backed by an expert installation team for pre-tensioning and post-tensioning job.

With profound expertise in offering pre-tensioning & post-tensioning solutions, Usha ISMAL serves various heavy civil engineering construction applications like bridges, elevated structures, metros, flyovers, silos, nuclear reactors, very high capacity water tanks in deserts, dams, rock & ground anchoring etc. across the globe. Usha ISMAL’s, complete pre-stressing solutions include system design, supply of different varieties of LRPC strands, anchorage accessories & necessary equipment, all under one roof at the state- of-the-art manufacturing facility, supported by an expert execution team for installation. The facility in Ranchi also has in-house heat treatment and electro-plating facilities. The manufacturing facility has been accredited by ISO 9001 quality system to ensure highest grade of quality products and services.

Usha Martin’s continued investment in technology and equipment consistently developed products to the highest quality standards. With years of engineering excellence, many new varieties of LRPC strands were added in the product range to keep pace with new concepts and applications.

Usha Martin product basket encompasses a comprehensive range of LRPC strands, namely:

LRPC strands of all available sizes and grades can be polymer sheathed and galvanised in conformance to major national and international specification.

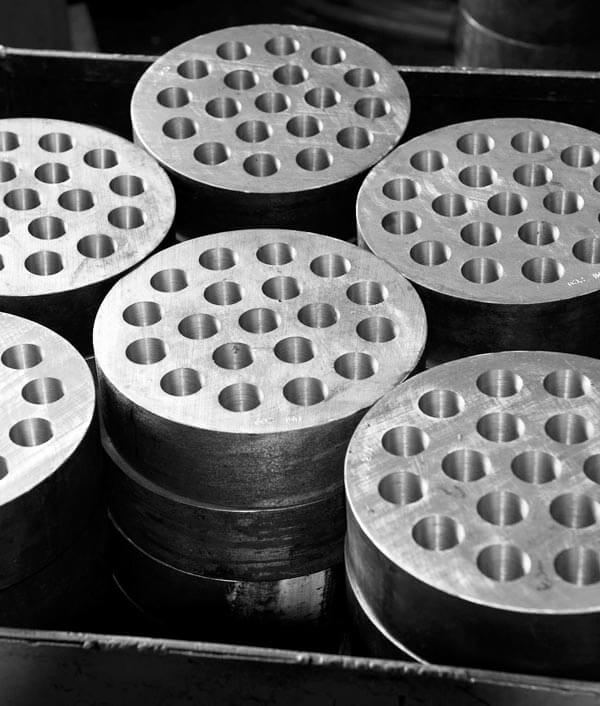

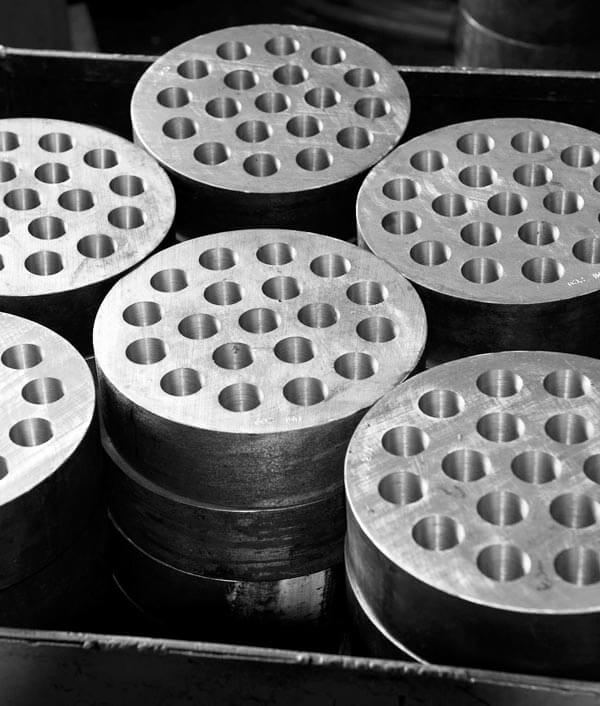

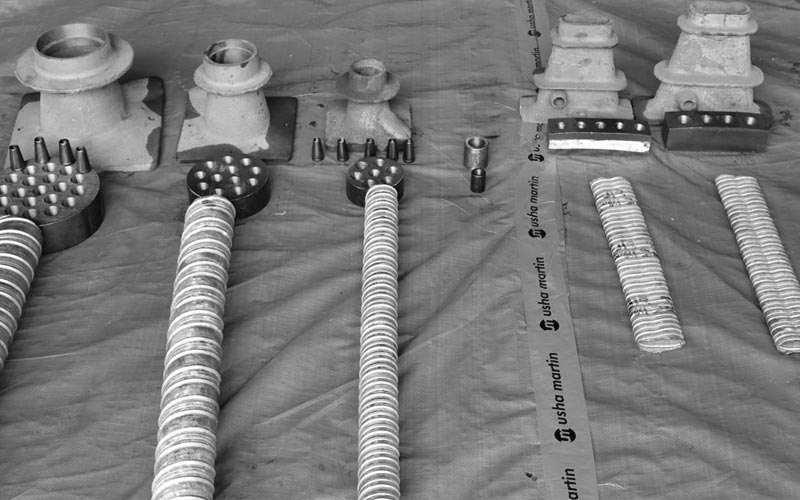

We being the pioneer in pre-stressing activities, have the necessary manufacturing infrastructure for supplying all types of components required in pre-stressing operation. Our anchorages are suitable for both round & flat type tendons. The anchorage set, comprising of Tube Unit, Sheathing Pipe, Bearing Plate and Ancharite Wedges are used in post-tensioning jobs; Wedge-grips and Barrels are used in pre-tensioning, both are well accepted world-wide for best in class quality.

Our anchorages are suitable for :

Round Tendon Systems - required in heavy civil structures like Metros, Flyovers, Bridges, Silos etc.

Flat Tendon Systems – required in PSC Slab Projects like Building Projects.

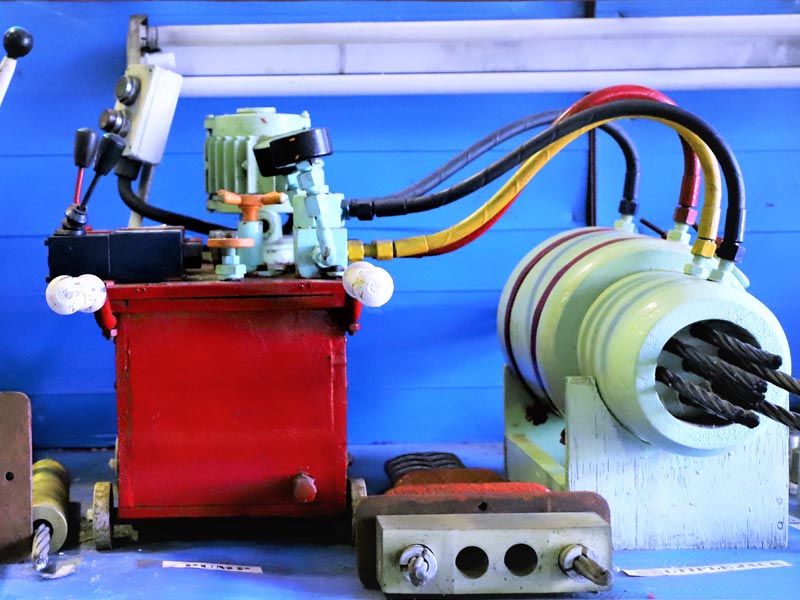

Pre-stressing activity call for deployment of various hydraulic and pneumatic equipment at the project site which have to perform with great accuracy and time bound performance.

We manufacture various Hydraulic Equipment:

Hydraulic Jacks

Powerpacks

Grout Pump & Grouting Agitator

Pre-stressing activities requires supply of anchorages, LRPC strand and on-site stressing services. Pre-stressing encompasses pre-positioning & post-positioning both internal and external. Usha Martin has a wide spread set-up for undertaking all types of pre-stressing jobs. Pre-stressing activities generally comprises of profiling pre-stressing tendon at the time of casting, stressing on achieving the strength of cast structure and grouting to remove the void spaces, thus making the tendon integral to the cast structure.

All the above activities are executed by UML expert site personnel using sophisticated hydraulic and pneumatic equipment, which are also manufactured in our state-of-art manufacturing plant located at Ranchi in India.

UML executed various pre-stressing activities for numerous applications like Buildings, Nuclear Reactor, Elevated Structure including Cement and Clinker Silos, Metro projects, Extra dosed bridges, Gigantic water tanks on desert area, Ground anchoring in Dams, Rock fall arrester, Soil Stabilization, High speed Railway projects and RRTS projects.

Usha Martin service team has a vast experience to execute all pre-stressing activities in many of such prestigious projects both in India and abroad.

We have the following testing facilities at our Ranchi plant both for pre-stressing materials and LRPC strand:

Both the above tests are conducted as per FIP 1993 and BS 4447:1973.

Special quality system testing is undertaken to manufacture high quality LRPC strands, which are best in its class.

Relaxation Testing Machine

Relaxation Testing Machine Breaking Load Testing Machine

Breaking Load Testing Machine

We are a company specializing in the manufacture of wire for use in a variety of products and applications. Pengg Usha Martin has achieved several international recognitions within the fields of automobile and mechanical engineering. Key attributes that set us apart are: highest degree of dimensional accuracy, precision in mechanical properties, thorough knowledge of the metallurgical processes and close working relationship with customers with focused attention on their requirements. These qualities also represent our motto and our standards.

Formed as a result of collaboration between Joh Pengg AG, Austria and Usha Martin Limited India, both world leaders in their respective fields, Pengg Usha Martin started operations in 2008 with a manufacturing facility built over 11.3 acres of land at Tatisilwai in Ranchi. The state-of-art facility comprises of 10,000 m2 of covered shed, equipped with three EOT cranes with a capacity of 5 MT each. Further, we draw power from the captive power plant owned by the parent company, which is backed up by a UPS and DG, to ensure uninterrupted production.

An overview of some of the key processes are as follows:

Shaving: This process is carried out to meet the most demanding specifications for certain products. A 300-micron thick layer of rod is shaved off to reduce surface defects, remove decarburization and eliminate harmful effects in the wire rod manufacturing process.

Patenting: This is done to achieve a particular fine-grained microstructure with excellent cold working properties. This process also ensures extreme uniform wire properties and allows higher tensile strength of products.

Wire Drawing: Latest state-of-the-art technology has been adopted in this process to ensure that the wire confirms to the required dimensions. The company believes in the importance of torsion-free, low-friction wire guides and thorough cooling in the wire drawing process.

Oil Hardening & Tempering: A continuous process to optimize wire properties, it is carried out by quenching the wire to martensite structure in oil, followed by tempering in a lead bath. This results in a stress-relieved, homogenous structure with no deformation texture. Our customers appreciate the durability of these wires, their excellent fatigue life, reliability when subjected to elevated operating temperatures and high resistance against relaxation.

Eddy Current Testing: Spring wire for the highest dynamic stresses is checked against surface flaws using electromagnetic in-line testing. This system catches defects and colors the surface defects to more than 40 microns depth using two independent probes. Additional sensors give further information regarding the quality of the wire. This enables non-destructive quality inspection and testing of the entire length of the wire. When combined with our strict finished goods inspection, the system guarantees highest quality products suitable for further processing.

Oil tempered SiCrV+Ni alloyed valve spring wire from shaved wire rod, with dia ≥ 2.5mm 40 μm-continuous surface inspected.

Application

For high dynamic stresses e.g., valve springs

Oil tempered SiCrV alloyed valve spring wire from shaved wire rod, with dia ≥ 2.5mm 40 μm-continuous surface inspected.

Similar Grades

Application

For high dynamic stresses e.g., valve springs

Oil tempered SiCrV alloyed valve spring wire with dia ≥ 2.5mm 60 μm-continuous surface inspected

Similar Grades

Application

For moderate dynamic stresses e.g., clutch coils

Oil tempered SiCrV alloyed spring wire

Similar Grades

Application

For statically stressed springs e.g., suspension springs

Oil tempered SiCr alloyed valve spring wire from shaved wire rod with diameters ≥ 2.5 mm 40 μm-continuous surface inspected

Similar Grades

Application

For high dynamic stresses e.g., valve springs

Oil tempered SiCr alloyed spring wire spring wire from shaved wire with diameters ≥ 2.5 mm 40 μm-continuous surface inspected

Similar Grades

Application

For dynamic stresses

Oil tempered SiCr alloyed spring wire with diameters ≥ 2.5 mm 60 μm-continuous surface inspected

Similar Grades

Application

For moderate dynamic stresses e.g., clutch springs

Oil tempered SiCr alloyed spring wire

Similar Grades

Application

For statically stressed springs e.g., suspension springs

Oil tempered unalloyed spring wire

Similar Grades

Application

For statically stressed springs

Since its inception, Pengg Usha Martin has successfully adopted and incorporated the vast experience of its parent companies, which has enabled it to deliver excellence to its customers every step of the way. Some of our key achievements and highlights are as follows.

Currently, we are the only company in India to manufacture oil hardened and tempered wires.

As a consistent market leader, we have a domestic market share of over 70%.

We are the first company in the world to get a BIS license for IS4454-Part 2.

We have doubled our capacity twice in 13 years since our inception.

We are IATF 16949, ISO14001 and ISO 45001 certified.

We have most advanced testing equipment. The success of our products is owed to their excellent performance, which is based on world class quality standards, supported by advanced infrastructure and technology.

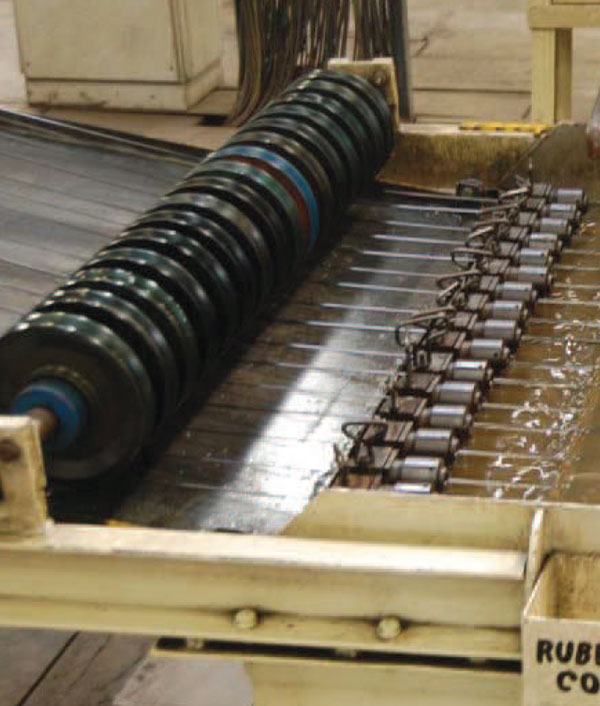

Usha Martin’s Machinery division located in Ranchi manufactures a wide range of industrial machines including Wire Drawing Machine, Stranding Machine, Wire Rope Closing Machine, Steel Plant Equipment, Material Handling Equipment, Bright Bar Manufacturing Machine, Armouring and Rewinding Machines, Copper Coating lines for CO2 Welding Wire. Our machinery division is a regular supplier of equipment to various leading Wire, Rope and Cable companies globally.

The facility is equipped with a modern machine shop having a fleet of CNC turning centers, machining centers, dynamic balancing machines, sophisticated measuring and inspection facilities. The fabrication shop is equipped with PUG cutting machine, SAW welding facilities with additional set-up for design and manufacturing of electrical panels. The company has highly skilled professionals to produce some of the best machines in the industry.

The Machinery Division of Usha Martin group was established in the year 1947 to manufacture wire drawing machines and allied equipment. Over the years, it has added a wide range of steel wire, wire rope and cable machineries to its product portfolio and is now a leader in the Indian and international markets. In its endeavor to deliver world-class machineries and services, the entity has also entered into technical collaborations with leading global manufacturers such as:

Wire Drawing Machine (Wet)

Used for drawing fine wires and have the dies submerged in fatty soap solution, which acts as a lubricant as well as coolant. Very compact, thus does not need much space.

Wire Drawing Machine (Dry - Bull Bloc)

Used particularly for production of large wire sizes for small batch quantities.

Wire Drawing Machine (Dry - Double Bloc)

Used for high speed drawing of ferrous wires, ideal for application of high carbon steel, spring, tyre bead wires, low carbon steel netting, fencing, nails and welding wires. Provides excellent cooling of wires between reductions. No axial twist of wires between blocks. High spindle efficiency.

Wire Drawing Machine (Dry – OTO)

Used for a variety of applications including PC wires, HCS wires, Stainless Steel and Non-Ferrous wires.

Wire Drawing Machine (Dry-Dancer Controlled either limited or full)

Machine designed for high performance, reliability and ease of maintenance.

Tubular Stranding & Closing Machine

The machines are rugged in construction and offer trouble-free operation with higher shop floor efficiency. The machines are characterised by:

Multi-layer strand can be produced with improved compactness, using our planetary stranding machines. We manufacture high quality specialised machines with customised offerings to meet your ideal requirement.

Bunching Machine

Sound proof guard with cooling provision, supported by latest generation digital AC vector drive, creates a competitive edge, to manufacture high performance Bunching Machines, giving every customers the assurance of world class quality and service.

We manufacture a comprehensive range of wire treatment lines for spooling & coiling solutions. At Usha Martin machinery division, we produce one of the most sophisticated and specialised machines to meet your requirements with top of the line expertise.

Innovation and speed are our key drivers. Consistency in offering high quality products and services form the foundation of our offerings. We provide best in class after sales support and services, some of which are featured below:

Hard coating of drum for dry drawing machines.

Experienced manpower - a strong technical team backed by state-of-art technology and equipment provides a competitive edge to our offerings.

Machine building, refurbishing, re-conditioning and re-engineering of machinery to its original specifications and performance levels.

Continuous monitoring, revamping and technology upgradation of machines.

Customized offerings with tailor made specifications to meet the exact requirements of clients.

Precision and quality have always been our hallmark. All the machines and components are thoroughly checked for quality and accuracy after they are assembled.

Machinery Division,

Tatisilwai, Ranchi,

Jharkhand - 835103.

This unit was set up in 1974 in the northern state of Punjab in India. It is spread over an area of 8 hectares and employs about 700 people, making it the largest wire & wire rope unit in Northern India. High quality wires and wire ropes that find application in Automobiles, Detonators, Textile, and other engineering sectors are manufactured at this facility. Special grade wire rods, after stringent quality checks, are processed through pickling, patenting, galvanizing, batch annealing facilities to produce high performance specialty wires and wire ropes. This unit has a unique expertise in galvanizing over very fine sized wires.

Usha Martin manufacture wires which caters to extremely demanding spring industry. Our spring steel wires are heat treated to meet customer specific requirements. Spring wires produced by us are one of the most preferred choice for springs manufacturers in automobile industry.

Usha Martin produces and supplies copper-coated MIG (CO2) welding wires from sophisticated in-line drawing and copper coating machines, to delight its users with a smooth flowing wire, stable arc and low spatter wire for welding.

Usha Martin’s GALSTAR™ wires are an innovative solution designed to deliver superior corrosion protection, significantly outperforming traditional zinc coatings. Manufactured with a zinc-aluminium alloy, these wires offer the combined benefits of zinc’s sacrificial protection and aluminium’s passivation, ensuring exceptional resistance to corrosion even after deformation or exposure to heat. This advanced coating technology eliminates the need for expensive, complex, and environmentally harmful post-coating treatments. GALSTAR™ wires are ideally suited for demanding applications such as rockfall and avalanche barriers, slope stabilization, gabions, fencing, automotive springs, and as core wires or strands in electrical conductors.

Usha Martin manufactures high-quality ACSR (Aluminium Conductor Steel Reinforced) wire and strands, widely used in power transmission lines for its superior conductivity, high mechanical strength, and long-term reliability. Specially designed to make it ideal for overhead transmission, capable of withstanding harsh environmental conditions.

Usha Martin’s wires are the most preferred choice in needle industry all across the globe. Our needle wires are manufactured from high carbon steel and are used to manufacture Hosiery Needles, Sewing Needles, Knitting Needles, Hooks, Fishing Hooks, Surgical Needles, etc.

We specialize in manufacturing high-quality industrial wires designed for various types of wire mesh and vibrating screens. Our wires are engineered for durability and performance, making them ideal for use in separation, filtration, and screening processes across various industries. With precise dimensional control and superior tensile strength, our wires ensure consistent performance even in the most demanding operating conditions.

We produce high-quality fishhook wires known for their high strength and excellent surface finish. Designed to meet the precise requirements of the fishing industry, these wires offer superior capabilities and resistance to corrosion, ensuring reliable performance in marine environments.

Usha Martin manufactures Cold Heading Quality wire with both fine grain and coarse grain steel depending on customers’ requirement through silicon killed/ aluminium killed steel. With the help of vacuum degassing facility, the levels of hydrogen, oxygen, and nitrogen are controlled in order to fulfil the requirements in critical applications.

Usha Martin is a preferred supplier of auto spoke wires in the automobile industry. Auto spoke wires manufactured by the company are known for their high quality performance and longer life.

Usha Martin manufactures a wide range of Brush wires catering to quality requirements in diversified applications such as Industrial Brushes, Power Brushes, Strip Mill Brushes, Tube Brushes, Scratch Brushes, Polymer coated stem wire in bottle brushes, Staple wire in domestic brushes & brooms.

The facility observes stringent quality control in its manufacturing process. Testing facilities like Tensile Testing, Torsion Testing, Bend Testing, Endurance Testing provides high quality products with superior performance. The processes are well documented and controlled in accordance with ISO 9001 and ISO 14001 Quality System.

We have expertise in providing a wide range of products designed for critical environments. The company’s facilities are equipped with the latest state-of-the-art high capacity equipments to manufacture world-class products.

Usha Martin Ltd.

Wire & Wire Rope Unit - North India,

Dharamshala Road, VPO: Chohal, Hoshiarpur, Punjab - 146024.

UM Cables is a dedicated manufacturer and exporter of high quality Telecommunication Cables, Fiber Reinforced Plastic Rods (FRP) and Impregnated Glass Fiber Rovings. It produces various types of cables including Optical Fiber Cable, Aerial Cables, Micro ducts, Hybrid category cables, FTTH/Drop Cables, Jelly Filled Copper Cables, Aerial Copper Cables and Duct Copper Cables etc. We offer FRP Rods ranging from 0.5mm to 3.5mm diameter available in both coated and un-coated types.

U M Cable believes in the modern day philosophy ‘Konnectitude’- connecting and meeting business needs globally, with the right spirit & positive attitude.

The company believes in continual improvement of its products by offering best-in-class solutions with the following advantages:

State-of-art Manufacturing Facility

At U M Cables Ltd., we use the most advanced manufacturing equipment sourced from the leading brands like Rosendahl, Medek & Schroner, Watson, Nokia, Kobe, Nextrom, Queins and Gouder.

The unit has a capacity to produce 1.2 million Kms of fiber optical cables, 0.75 million Kms of conductor copper cables and 0.5 million Kms of FRP Rods. The facility is ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 certified.

We are leading manufacturer & exporter of Optical Fiber Cable since year 2000. We believe in continual improvement in our product by offering best solutions based on Faster Communications, Less Expensive, Low signal loss, Usage of less energy, Low risk of injury, Flexible, Smaller in dimensions, High data carrying capacity, High security & Light weight cable.

Manufacturing Range

We also pride ourselves in manufacturing the very best Copper Telecommunication Cable with very high purity of copper, with high conductivity, precise manufacturing capability for high performance of cable.

Manufacturing Range

We do have manufacturing of high technology FRP Rods which are used in manufacturing of Optical Fiber Cables, to increase strength of cable radially & axially. It provide anti – buckling property which can be used at center of the core or embedded with outer sheath / jacket material. We have good presence in both India & abroad Fibre Reinforced Rod (FRP) market.

Manufacturing Range

We are also manufacturer of impregnated Glass Fiber Roving (IGFR) to increase peripheral strength of Optical Fiber Cable and protect cable from attack of rodent & termites

Manufacturing Range

Key Facilities

At U M Cables Ltd, we use the most advanced manufacturing equipment sourced from the leading brands like Rosendahl, Medek & Schroner, Watson, Nokia, Kobe, Nextrom, Queins and Gouder.

The unit has capacity to produce 1.2 million fiber km of fiber optical cable, 0.75 million conductor kilometer of copper cable and 0.5 million km of FRP Rods. The facility is certified with ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018.

UM Cables Ltd.

Survey No. 1/1/3, Chinchpada,

Silvassa - 396 230.