We are a company specializing in the manufacture of wire for use in a variety of products and applications. Pengg Usha Martin has achieved several international recognitions within the fields of automobile and mechanical engineering. Attributes that sets us apart, is the highest degree of dimensional accuracy, precision in mechanical properties, thorough knowledge of the metallurgical processes and close working relationship with our customers with focused attention on their requirements. These qualities represent at the same time, our motto and our standards.

Formed as a result of collaboration between Joh Pengg AG, Austria and Usha Martin Limited India, both world leaders in their respective fields, Pengg Usha Martin started operations in 2008 with a manufacturing facility built over 11.3 acres of land at Tatisilwai in Ranchi. The state-of-art comprises of 10,000 m2 covered shed, equipped with three EOT cranes with a capacity of 5 MT each. Further, we draw power from the captive power plant owned by the parent company, which is backed up by a UPS and DG, to ensure uninterrupted production.

An overview of some of the key processes are as follows:

Shaving: For products satisfying the most demanding specifications, a 300-micron thick layer of rod is shaved off to reduce surface defects, remove decarburization and eliminate harmful effects in the wire rod manufacturing process.

Patenting: To achieve a particular fine-grained microstructure with excellent cold working properties. This process also ensures extreme uniform wire properties and allows higher tensile end products.

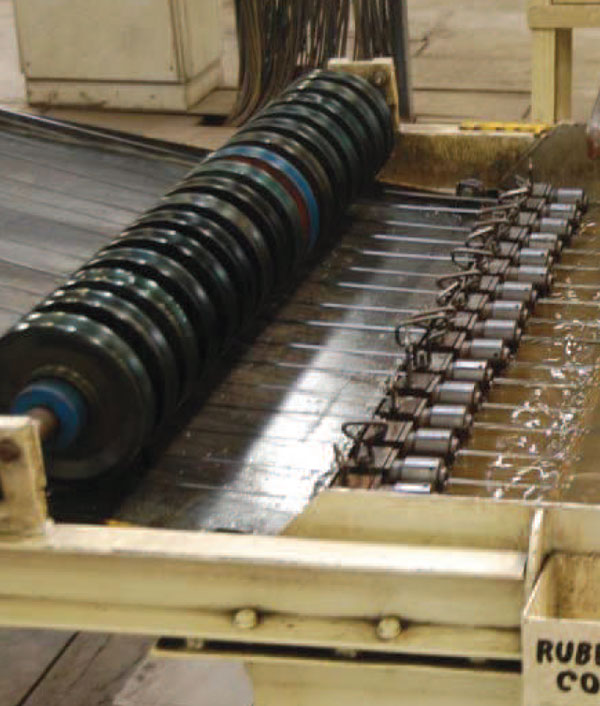

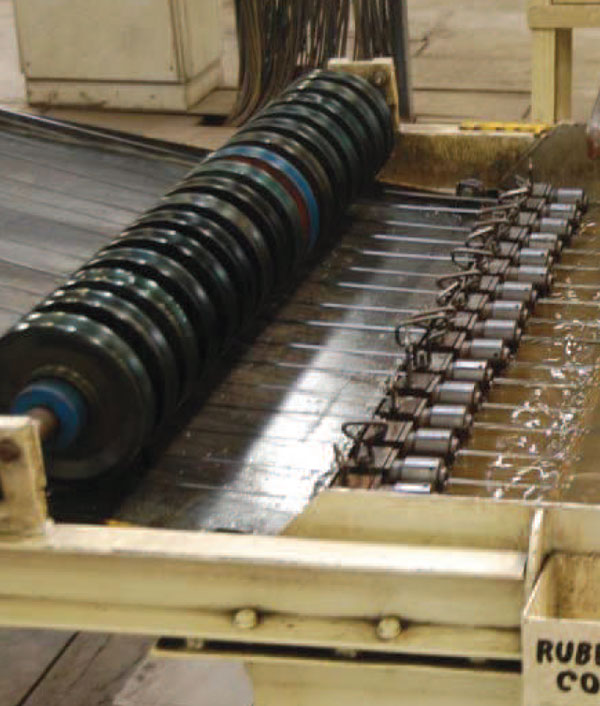

Wire Drawing: Adapted latest state-of-the-art technology to ensure that the wire confirms to the required dimensions. We believe in the importance of torsion-free, low-friction wire guides and thorough cooling in the wire drawing process.

Oil Hardening & Tempering: A continuous process to optimize wire properties, it is carried out by quenching the wire to martensite structure in oil, followed by tempering in a lead bath. This results in a stress-relieved, homogenous structure with no deformation texture. Our customers appreciate the durability of these wires, their excellent fatigue life, reliability when subjected to elevated operating temperatures and high resistance against relaxation.

Eddy Current Testing: Spring wire for the highest dynamic stresses is checked against surface flaws using electromagnetic in-line testing. This system catches defects and colors the surface defects to more than 40 microns depth using two independent probes. Additional sensors give further information regarding the quality of the wire.

This enables the non-destructive quality inspection and testing of the entire length of wire. When combined with our strict finished goods inspection, the system guarantees highest quality products suitable for further processing.

Oil tempered SiCrV+Ni alloyed valve spring wire from shaved wire rod, with dia ≥ 2.5mm 40 μm-continuous surface inspected.

Application

For high dynamic stresses e.g., valve springs

Oil tempered SiCrV alloyed valve spring wire from shaved wire rod, with dia ≥ 2.5mm 40 μm-continuous surface inspected.

Similar Grades

Application

For high dynamic stresses e.g., valve springs

Oil tempered SiCrV alloyed valve spring wire with dia ≥ 2.5mm 60 μm-continuous surface inspected

Similar Grades

Application

For moderate dynamic stresses e.g., clutch coils

Oil tempered SiCrV alloyed spring wire

Similar Grades

Application

For statically stressed springs e.g., suspension springs

Oil tempered SiCr alloyed valve spring wire from shaved wire rod with diameters ≥ 2.5 mm 40 μm-continuous surface inspected

Similar Grades

Application

For high dynamic stresses e.g., valve springs

Oil tempered SiCr alloyed spring wire spring wire from shaved wire with diameters ≥ 2.5 mm 40 μm-continuous surface inspected

Similar Grades

Application

For dynamic stresses

Oil tempered SiCr alloyed spring wire with diameters ≥ 2.5 mm 60 μm-continuous surface inspected

Similar Grades

Application

For moderate dynamic stresses e.g., clutch springs

Oil tempered SiCr alloyed spring wire

Similar Grades

Application

For statically stressed springs e.g., suspension springs

Oil tempered unalloyed spring wire

Similar Grades

Application

For statically stressed springs