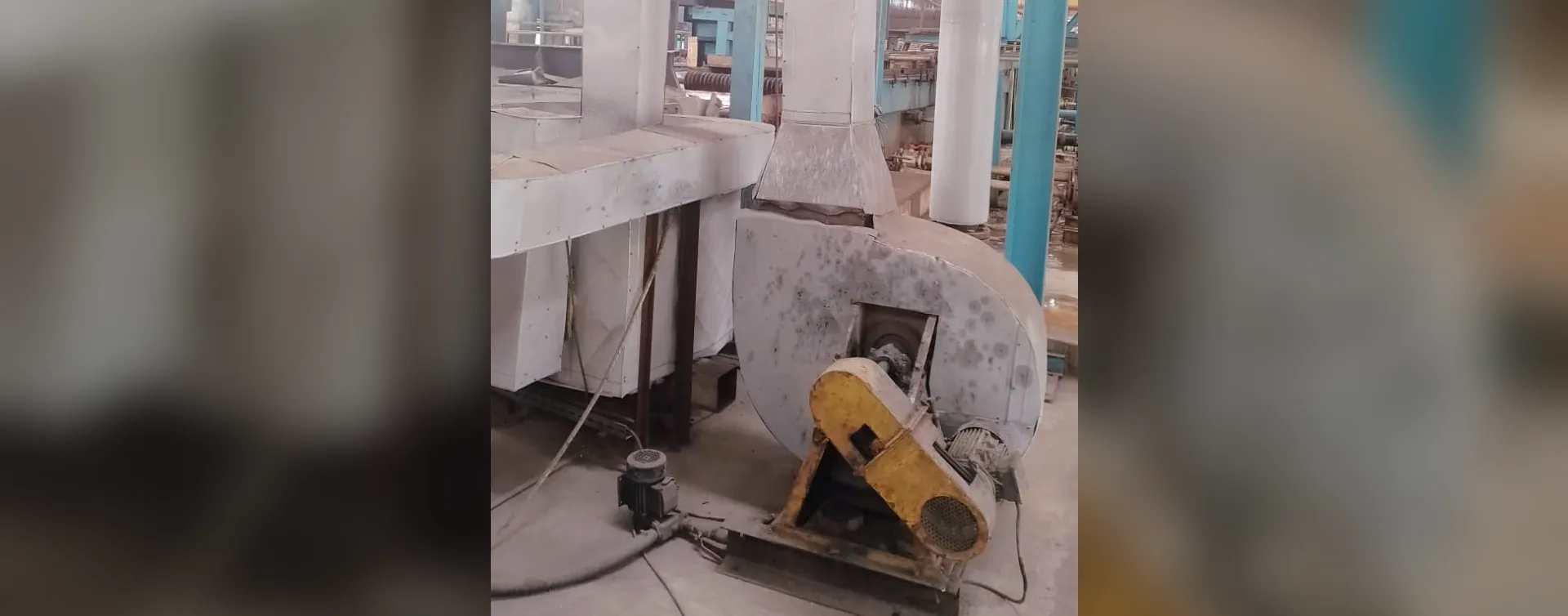

In line with Usha Martin Limited’s commitment to improving energy efficiency, a targeted intervention was implemented at the DSW (Drawn Steel Wire) line to optimize heat utilization in the flux drying process. Historically, the drying system relied on electric heaters that consumed significant amounts of power during extended daily operations. With energy being a major cost and emissions driver in these processes, the team explored opportunities to tap into unused thermal energy elsewhere in the system. A waste heat recovery system was installed to capture residual heat from the lead bath, an adjacent process operating at elevated temperatures. This heat was redirected to support the drying of flux, significantly reducing the reliance on electric heating. By repurposing residual heat from the adjacent lead bath, the system now significantly reduces the energy demand from electric heaters. Daily energy consumption dropped from 648 kWh to 120 kWh, resulting in a daily saving of 528 kWh. On an annualized basis, this equates to an estimated energy saving of 193 MWh and cost savings of approximately 1.064 million INR.